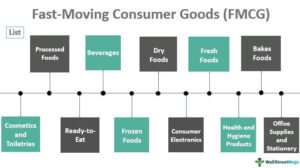

Ideas for Fmcg goods distributor on How to maintain excellent inventory

In expanding new markets, best brands stay on top of the entire sales process and critically analyse the deal.

How can you stay on top of your sales process if you aren’t engaged in it each step of the way?

Product distribution is one important step that often goes overlooked as brands opt for the cheapest or easiest option rather than devising a legitimate distribution strategy.

Importance of inventory management

As a part of your supply chain, inventory management includes aspects such as controlling and overseeing purchases — from suppliers as well as customers — maintaining the storage of stock, controlling the amount of product for sale, and order fulfillment.

Naturally, your company’s precise inventory management meaning will vary based on the types of products you sell and the channels you sell them through. But as long as those basic ingredients are present, you’ll have a solid foundation to build upon.

Inventory is the biggest asset to your company, so in order to save money and make money, you need to protect that asset and nurture it in the right direction. Without implementing inventory management techniques, you’ll never get ahead.

As consumers reset the expectations of fulfillment to being fast and free, and buying journeys, regardless of channel, become heavily influenced by digital interactions, retailers and B2B businesses are adapting their operations to support new initiatives to meet those expectations.

What could make a successful wholesale distribution business now and beyond? Attributes such as good inventory handling and excellent relationships with customers still stand. However, using technology to provide ease and convenience is the new norm.

If you run a wholesale distribution business, you know that order volumes are huge and need to be fulfilled as soon as possible. This means that your own backend system for inventory control must be foolproof. By building into your business those features that give your customers the convenience they want, you can ensure long-term success

Retail inventory management

Retail is the broadest catch-all term to describe business-to-consumer (B2C) selling. There are essentially two types of retail separated by how and where a sale takes place.

- First, online retail (eCommerce) where the purchase takes place digitally.

- Second, offline retail where the purchase is physical through a brick-and-mortar storefront or a salesperson.

Wholesale, on the other hand, refers to business-to-business (B2B) selling. Knowing the differences and best practices of retail and wholesale is critical to success.

Most businesses maintain stock across multiple channels as well as in multiple locations. The diversity of retail inventory management adds to its complexity and drives home its importance to your brand.

Basics of Inventory management

Small-to-medium businesses (SMBs) often use Excel, Google Sheets, or other manual tools to keep track of inventory databases and make decisions about ordering.

However, knowing when to reorder, how much to order, where to store stock, and so on can quickly become a complicated process. As a result, many growing businesses graduate to an inventory management app, software, or system with capabilities beyond manual databases and formulas.

With these systems, the procedures of inventory management extend beyond basic reordering and stock monitoring to encompass everything from end-to-end production and business management to lead time and demand forecasting to metrics, reports, and even accounting.

Importance of inventory management

For any goods-based businesses, the value of inventory cannot be overstated, which is why inventory management benefits your operational efficiency and longevity.

From SMBs to companies already using enterprise resource planning (ERP), without a smart approach, you’ll face an army of challenges, including blown-out costs, loss of profits, poor customer service, and even outright failure.

From a product perspective, the importance of inventory management lies in understanding what stock you have on hand, where it is in your warehouse(s), and how it’s coming in and out.

Clear visibility helps you:

- Reduce costs

- Optimize fulfillment

- Provide better customer service

- Prevent loss from theft, spoilage, and returns

In a broader context, inventory management also provides insights into your financial standing, customer behaviors and preferences, product and business opportunities, future trends, and more.

Inventory management terms

- Barcode scanner

- Physical devices used to check-in and check-out stock items at in-house fulfillment centers and third-party warehouses.

- Bundles

- Groups of products that are sold as a single product: selling a camera, lens, and bag as one SKU.

- Cost of goods sold (COGS)

- Direct costs associated with production along with the costs of storing those goods.

- Deadstock

- Items that have never been sold to or used by a customer (typically because it’s outdated in some way).

- Decoupling inventory

- Also known as safety stock or decoupling stock; refers to inventory that’s set aside as a safety net to mitigate the risk of a complete halt in production if one or more components are unavailable.

- Economic order quantity (EOQ)

- EOQ refers to how much you should reorder, taking into account demand and your inventory holding costs.

- Holding costs

- Also known as carrying costs; the costs your business incurs to store and hold stock in a warehouse until it’s sold to the customer.

- Landed costs

- These are the costs of shipping, storing, import fees, duties, taxes and other expenses associated with transporting and buying inventory.

- Lead time

- The time it takes a supplier to deliver goods after an order is placed along with the timeframe for a business’ reordering needs.

- Order fulfillment

- The complete lifecycle of an order from the point of sale to pick-and-pack to shipping to customer delivery.

- Order management

- Backend or “back office” mechanisms that govern receiving orders, processing payments, as well as fulfillment, tracking and communicating with customers.

- Purchase order (PO)

- Commercial document (B2B) between a supplier and a buyer that outlines types, quantities, and agreed prices for products or services.

- Pipeline inventory

- Any inventory that is in the “pipeline” of a business’ supply chain — e.g., in production or shipping — but hasn’t yet reached its final destination.

- Reorder point

- Set inventory quotas that determine when reordering should occur, taking into account current and future demand as well as lead time(s).

- Safety stock

- Also known as buffer stock; inventory held in a reserve to guard against shortages.

- Sales order

- The transactional document sent to customers after a purchase is made but before an order is fulfilled.

- Stock keeping unit (SKU)

- Unique tracking code (alphanumeric) assigned to each of your products, indicating style, size, color, and other attributes.Third-party logistics (3PL)

- Third-party logistics refers to the use of an external provider to handle part or all of your warehousing, fulfillment, shipping, or any other inventory-related operation. Fourth-party logistics (4PL) takes this a step further by managing resources, technology, infrastructure, and full-scale supply chain solutions for businesses.

- Variant

- Unique version of a product, such as a specific color or size.

Common Inventory management mistakes

Another problem is inaccurate inventory records. This can be caused by batch processing or system latency due to higher than-planned inventory actions such as web and call center searches, items being reserved for a cart and orders being placed.

However, if you have inaccurate inventory information, you run the risk of:

– overpromising on inventory you don’t have.

– losing sales you could have made with replenishment inventory that hasn’t updated yet.

– unexpected expedited shipping charges because inventory isn’t

where you thought it was.

– not being able to expand your sales channels because you can’t meet marketplace SLAs regarding inventory accuracy and meeting your customer promise dates.

The last issue many companies see is balancing safety stock. Without enough safety stock you can lose sales and disappoint your customers and potentially lose them forever. Too much safety stock means big markdowns and lost margins at the end of the season or when the inventory is old or outdated. Balancing safety stock is even more difficult if you have silos or segmented inventory because you

cannot share safety stock across your entire organization to keep your inventory carry costs down.

.

What Is Inventory Management?

Inventory management is a step in the supply chain where inventory and stock quantities are tracked in and out of your warehouse.

The goal of inventory management systems is to know where your inventory is at any given time and how much of it you have in order to manage inventory levels correctly.

Some companies may opt to scan in inventory via a barcode scanner to increase efficiency along pick routes and accuracy.

Unlike an ERP system, an inventory management system focuses on one supply chain process. They often come with the ability to integrate with other software systems – point of sale, channel management, shipping – so you can build a personalized integration stack to the needs of your unique business.

Need for Inventory Management

1. Economic order quantity.

Economic order quantity, or EOQ, is a formula for the ideal order quantity a company needs to purchase for its inventory with a set of variables like total costs of production, demand rate, and other factors.

The overall goal of EOQ is to minimize related

costs. The formula is used to identify the greatest number of product units to order to minimize buying. The formula also takes the number of units in the delivery of and storing of inventory unit costs. This helps free up tied cash in inventory for most companies.

2. Minimum order quantity.

On the supplier side, minimum order quantity (MOQ) is the smallest amount of set stock a supplier is willing to sell. If retailers are unable to purchase the MOQ of a product, the supplier won’t sell it to you.

For example, inventory items that cost more to produce typically have a smaller MOQ as opposed to cheaper items that are easier and more cost effective to make.

Picture a successful retail business in your head. Maybe you’re picturing a small local shop, or a huge corporate business.

What do these two companies have in common?

Do they both consistently have the products in stock that you want?

Do they both carry goods in-store and online?

If the answers are yes, both retailers probably have a good handle on their physical inventories. And it’s even more likely they’re using inventory management software to do so.

Inventory management is the basis of a well-functioning retail business. Inventory management systems track the lifecycle of inventory and stock as it comes and goes out of your business.

When businesses don’t have a handle on the activity of their inventory, or worse, track it with outdated spreadsheets and data entry, the rest of the pieces, like order fulfilment, don’t fall into place.

When you don’t know how much inventory you have on hand, you can’t make smart reorder decisions

You can’t list items accurately online because you don’t have visibility into how much inventory you have to allocate to each channel. You get stuck with too much inventory or an incorrect amount of product. The list is endless.

Inventory management processes are imperative to succeed as a retailer of any kind — ecommerce, m

Why Is Inventory Management Important

Inventory management is the fundamental building block to longevity. When your inventory is properly organized, the rest of your supply-chain management will fall into place. Without it, you risk a litany of mistakes like mis-shipments, out of stocks, overstocks, mis-picks, and so on.

Proper warehouse management is key. Mis-picks result from incorrect paper pick lists, disorganized shelf labels, or just a messy warehouse in general. Mis-shipments are a direct result of mis-picks at the beginning of the inventory process, and are also a result of a lack in quality control procedures.

Out of stocks and overstocks occur when a company uses manual methods to place orders without having a full grasp on the state of their inventory. This is a not a good predictor for inventory forecasting and results in too much stock or too little.

All of these mistakes will not only cost you money, but also cost you in wasted labor spent correcting the mistakes later. When you don’t implement management tools, your risk of human error mistakes goes up by the minute. And your customer reviews and loyalty take a negative hit as well.

Inventory Management Techniques

That being said, inventory management is only as powerful as the way you use it.

It’s well worth the extra time and money to have inventory management set up by the experts who made the software. Work with them to make sure you’re utilizing the proper techniques and features to get the most bang for your buck.

Let’s take a look at some inventory-control techniques you may choose to utilize in your own warehouse.

1. Economic order quantity.

Economic order quantity, or EOQ, is a formula for the ideal order quantity a company needs to purchase for its inventory with a set of variables like total costs of production, demand rate, and other factors.

The overall goal of EOQ is to minimize related costs. The formula is used to identify the greatest number of product units to order to minimize buying. The formula also takes the number of units in the delivery of and storing of inventory unit costs. This helps free up tied cash in inventory for most companies.

2. Minimum order quantity.

On the supplier side, minimum order quantity (MOQ) is the smallest amount of set stock a supplier is willing to sell. If retailers are unable to purchase the MOQ of a product, the supplier won’t sell it to you.

For example, inventory items that cost more to produce typically have a smaller MOQ as opposed to cheaper items that are easier and more cost effective to make.

3. ABC analysis.

This inventory categorization technique splits subjects into three categories to identify items that have a heavy impact on overall inventory cost.

- Category A serves as your most valuable products that contribute the most to overall profit.

- Category B is the products that fall somewhere in between the most and least valuable.

- Category C is for the small transactions that are vital for overall profit but don’t matter much individually to the company altogether.

Picture a successful retail business in your head. Maybe you’re picturing a small local shop, or a huge corporate business.

What do these two companies have in common?

Do they both consistently have the products in stock that you want?

Do they both carry goods in-store and online?

If the answers are yes, both retailers probably have a good handle on their physical inventories. And it’s even more likely they’re using inventory management software to do so.

Inventory management is the basis of a well-functioning retail business. Inventory management systems track the lifecycle of inventory and stock as it comes and goes out of your business.

When businesses don’t have a handle on the activity of their inventory, or worse, track it with outdated spreadsheets and data entry, the rest of the pieces, like order fulfilment, don’t fall into place.

When you don’t know how much inventory you have on hand, you can’t make smart reorder decisions

You can’t list items accurately online because you don’t have visibility into how much inventory you have to allocate to each channel. You get stuck with too much inventory or an incorrect amount of product. The list is endless.

Inventory management processes are imperative to succeed as a retailer of any kind — ecommerce, multi-channel, brick-and-mortar, omni-channel — if you want to seriously compete.

Let’s take a look at a few stats from actual retailers who have experienced the hurdles of not using an inventory management software.

- 43% of retailers ranked inventory management as their number one day-to-day challenge

- Over 1,600 new warehouses were opened between 2013 and 2017

With new warehouses opening every day, the amount of people in need of proper inventory management processes grows in congruence with the amount of people who don’t know how to manage them. The importance of inventory management simply cannot be ignored.

What Is Inventory Management?

Inventory management is a step in the supply chain where inventory and stock quantities are tracked in and out of your warehouse.

The goal of inventory management systems is to know where your inventory is at any given time and how much of it you have in order to manage inventory levels correctly.

Some companies may opt to scan in inventory via a barcode scanner to increase efficiency along pick routes and accuracy.

Unlike an ERP system, an inventory management system focuses on one supply chain process. They often come with the ability to integrate with other software systems – point of sale, channel management, shipping – so you can build a personalized integration stack to the needs of your unique business.

Why Is Inventory Management Important

Inventory management is the fundamental building block to longevity. When your inventory is properly organized, the rest of your supply-chain management will fall into place. Without it, you risk a litany of mistakes like mis-shipments, out of stocks, overstocks, mis-picks, and so on.

Proper warehouse management is key. Mis-picks result from incorrect paper pick lists, disorganized shelf labels, or just a messy warehouse in general. Mis-shipments are a direct result of mis-picks at the beginning of the inventory process, and are also a result of a lack in quality control procedures.

Out of stocks and overstocks occur when a company uses manual methods to place orders without having a full grasp on the state of their inventory. This is a not a good predictor for inventory forecasting and results in too much stock or too little.

All of these mistakes will not only cost you money, but also cost you in wasted labor spent correcting the mistakes later. When you don’t implement management tools, your risk of human error mistakes goes up by the minute. And your customer reviews and loyalty take a negative hit as well.

Inventory Management Techniques

That being said, inventory management is only as powerful as the way you use it.

It’s well worth the extra time and money to have inventory management set up by the experts who made the software. Work with them to make sure you’re utilizing the proper techniques and features to get the most bang for your buck.

Let’s take a look at some inventory-control techniques you may choose to utilize in your own warehouse.

1. Economic order quantity.

Economic order quantity, or EOQ, is a formula for the ideal order quantity a company needs to purchase for its inventory with a set of variables like total costs of production, demand rate, and other factors.

The overall goal of EOQ is to minimize related costs. The formula is used to identify the greatest number of product units to order to minimize buying. The formula also takes the number of units in the delivery of and storing of inventory unit costs. This helps free up tied cash in inventory for most companies.

2. Minimum order quantity.

On the supplier side, minimum order quantity (MOQ) is the smallest amount of set stock a supplier is willing to sell. If retailers are unable to purchase the MOQ of a product, the supplier won’t sell it to you.

For example, inventory items that cost more to produce typically have a smaller MOQ as opposed to cheaper items that are easier and more cost effective to make.

3. ABC analysis.

This inventory categorization technique splits subjects into three categories to identify items that have a heavy impact on overall inventory cost.

- Category A serves as your most valuable products that contribute the most to overall profit.

- Category B is the products that fall somewhere in between the most and least valuable.

- Category C is for the small transactions that are vital for overall profit but don’t matter much individually to the company altogether.

4. Just-in-time inventory management.

Just-in-time (JIT) inventory management is a technique that arranges raw material orders from suppliers in direct connection with production schedules.

JIT is a great way to reduce inventory costs. Companies receive inventory on an as-needed basis instead of ordering too much and risking dead stock. Dead stock is inventory that was never sold or used by customers before being removed from sale status.

5. Safety stock inventory.

Safety stock inventory management is extra inventory being ordered beyond expected demand. This technique is used to prevent stockouts typically caused by incorrect forecasting or unforeseen changes in customer demand.

7. FIFO and LIFO.

LIFO and FIFO are methods to determine the cost of inventory. FIFO, or First in, First out, assumes the older inventory is sold first. FIFO is a great way to keep inventory fresh.

LIFO, or Last-in, First-out, assumes the newer inventory is typically sold first. LIFO helps prevent inventory from going bad.

8. Reorder point formula.

The reorder point formula is an inventory management technique that’s based on a business’s own purchase and sales cycles that varies on a per-product basis. A reorder point is usually higher than a safety stock number to factor in lead time.

9. Batch tracking.

Batch tracking is a quality control inventory management technique wherein users can group and monitor a set of stock with similar traits. This method helps to track the expiration of inventory or trace defective items back to their original batch.

10. Consignment inventory.

If you’re thinking about your local consignment store here, you’re exactly right. Consignment inventory is a business deal when a consigner (vendor or wholesaler) agrees to give a consignee (retailer like your favorite consignment store) their goods without the consignee paying for the inventory upfront. The consigner offering the inventory still owns the goods and the consignee pays for them only when they sell.

11. Perpetual inventory management.

Perpetual inventory management is simply counting inventory as soon as it arrives. It’s the most basic inventory management technique and can be recorded manually on pen and paper or a spreadsheet.

12. Dropshipping.

Dropshipping is an inventory management fulfillment method in which a store doesn’t actually keep the products it sells in stock. When a store makes a sale, instead of picking it from their own inventory, they purchase the item from a third party and have it shipped to the consumer. The seller never sees our touches the product itself.

13. Lean Manufacturing.

Lean is a broad set of management practices that can be applied to any business practice. It’s goal is to improve efficiency by eliminating waste and any non value-adding activities from daily business.

14. Six Sigma.

Six Sigma is a brand of teaching that gives companies tools to improve the performance of their business (increase profits) and decrease the growth of excess inventory.

15. Lean Six Sigma.

Lean Six Sigma enhances the tools of Six Sigma, but instead focuses more on increasing word standardization and the flow of business.

16. Demand forecasting.

Demand forecasting should become a familiar inventory management technique to retailers. Demand forecasting is based on historical sales data to formulate an estimate of the expected forecast of customer demand. Essentially, it’s an estimate of the goods and services a company expects customers to purchase in the future.

17. Cross-docking.

Cross-docking is an inventory management technique whereby an incoming truck unloads materials directly into outbound trucks to create a JIT shipping process. There is little or no storage in between deliveries.

18. Bulk shipments.

Bulk shipments is a cost efficient method of shipping when you palletize inventory to ship more at once.

Say “yes” more often to customers

See all inventory on hand across disparate systems and silos

Get accurate, scalable inventory views

Meet peak-period demand, avoid overpromising, lost sales and rush charges

Maximize inventory return on investment

Reduce safety stock and carrying costs, and increase inventory turns

Few ways to handle your wholesale distribution business successfully

More than 50% of retailers have said that ‘inventory visibility across all channels’ was the most important omnichannel capability.2 Whether inventory is located in a warehouse, a distribution center, a physical storefront or on a truck somewhere, you cannot make fulfillment

promises to your customers without an accurate inventory picture

Fulfillment and inventory managers don’t always have visibility into accurate inventory levels. This leads to lost sales, customers aggravated by overpromising, giving away margin due to markdowns and expedited shipping charges, carrying excess safety stock and limited ability to enter new sales channel

There are several aspects of successful inventory management, the first of which is maintaining just enough stock to do business. As a wholesale distributor, it may seem logical to stock up more to fulfill orders. Compared to pure retail business, this may be true in terms of volume.

However, more stock and more volume are often not the same things. While you may be buying and selling greater stock volumes, it is still important not to stock more than you need. Inventory calculations such as lead time, reorder level and safety stock apply to wholesale distribution as well. Ensuring you have no dead stock can in itself help you turn a profit.

The second aspect of inventory control is the ‘how’ of it. While you may be keen to use spreadsheets to track inventory, this is not ideal, especially when you have large volumes of stock moving around. An accurate view of your inventory can help prevent stock losses and misplaced orders. To do this, it is recommended that you use a good inventory management system. It can help you track your orders across channels much more effectively and keep a close eye on stock movement.

Say “yes” more often to customers

See all inventory on hand across disparate systems and silos

Get accurate, scalable inventory views

Meet peak-period demand, avoid overpromising, lost sales and rush charges

Maximize inventory return on investment

Reduce safety stock and carrying costs, and increase inventory turns

Use B2B E-commerce To Your Advantage

More than half of all B2B retailers say that a third of their sales come from online channels. Why should you fall behind?

E-commerce for B2B sales may not seem like the best idea. But in the digital age, it is growing at a hitherto unprecedented rate. Let’s not deny it- it is simply easier to buy things online, as we have seen in the growth of E-commerce in every possible retail sub-sector. B2B customers also feel this way, and an increasing number of buyers are shifting

B2B customers also feel this way, and an increasing number of buyers are shifting to their wholesale distributor’s website to make purchases of larger volumes. Secure transactions, a digital trail and the ease of browsing and buying products on an e-commerce store drive sales here.

If you haven’t already, now is the time to set up an e-commerce page that can handle large order volumes and also provides detailed descriptions that your target buyers will find useful.

Don’t Use Price To Compete

As a wholesale retailer, you can offer excellent discounts on products that make your offering more lucrative. However, in today’s intensely competitive B2B sales environment, competing on price can prove risky and it is only a matter of time before someone else comes along with better discounts.

Instead of reducing your price offering, compete on customer service and satisfaction. If you promise a delivery timeline of ten days, aim to deliver within seven. Keep your order history on the track and send alerts to your buyers periodically to make repeat purchases from you. Many wholesale distributors are leveraging email marketing to achieve this connection with their buyers.

Needless to say, ensure that you only sell products of the highest quality- you can gauge this by the number of returns you receive from an order. If you can build trust, in your product and your service, customers will keep coming back to you even if there are relatively cheaper alternatives available elsewhere.

Be On Top Of Your Cash Flow

Free cash flow is the basis of any good retail business, more so for a wholesale business where order sizes and prices are quite significant. Wholesalers often feel compelled to offer extended credit to their consumers. While credit and the practice of extending it to vendors are quite common in wholesale distribution, avoid falling into the overextension trap.

Set limits on how long a buyer’s credit period can extend. You can calculate this based on your estimated free cash flow for the next quarter or so. Calculate how much cash in hand you would need to continue fulfilling orders and procuring inventory. Set a credit limit, both in terms of time and money, based on these calculations.

Communicate clearly to your buyers that your credit terms are set in stone, and further orders will only be fulfilled once the accumulated credit is settled. While it may seem like a draconian approach to take to cash flow, not having enough working capital can drive you out of business, so it is important to follow through on your terms.

Rethink Your Order Fulfilment

How long does it take for you to fulfill an order if you already have inventory on hand? Several retailers today are able to ship an order out in less than 24 hours, setting standards for others to follow. Even in wholesale distribution where volumes are large, you can ship products out quickly if you have a process in place to do so.

First, digitize your order fulfillment. This way, you don’t have to manually write out and process each order at every stage. Ideally, once you receive an order, your warehouse personnel must receive an immediate update and should begin processing the order. Using technology makes this possible, even if your warehouses are spread across locations.

Then, consolidate your B2B sales from different channels. You may have an e-commerce B2B page as well as a field sales channel. Consolidate inventory across both channels so that you always have enough stock to actually fulfill an order.

A second approach that works for many in the industry is the use of back-ordering. If some products in your catalog have a short lead time, it is a sensible choice to only order those products into your inventory when you actually have an order for them. This way, you save on working capital. You can also consider drop shipping to help reduce the order fulfillment time.

Retailers increasingly find that their own customers expect faster order fulfillment. So, they look to you to fulfill their orders faster so they can keep up.

Build Relationships With Customers

Lasting relationships mean lasting business. Hence, focus on building relationships. Ensure that you maintain transparency at all times. Communicate with your customers about new products and offers on B2B purchases. If your policies have changed, ensure that a written update goes out to all customers.

Use email marketing to your advantage like several other wholesale distributors already do. A simple newsletter that provides useful information every month can build recall value. Be sure to track your customer outreach efforts to see what works.

Common Inventory Management Questions

The main goal of inventory management is to increase the visibility and organization of inventory activity via automated and streamlined pick/pack/ship features.

This kind of change empowers your small business to grow with confidence and puts you in front of the kind of customers you want.

Your business should run like a well-oiled machine upon implementing smart inventory

How do you measure to see if you are successfully managing inventory?

The proof is in the numbers when measuring the success rate of inventory management. After you have implemented new inventory management techniques, compare the data from before and after.

Have your level of mis-shipments, mis-picks, or out of stocks decreased? What about dead stock? Have you eliminated the dead piles of inventory around the perimeter of the warehouse?

If you can answer yes to these, you’ve successfully conducted inventory management. As a result, you can expect to see better customer reviews, improved customer loyalty, and even a boost in Amazon Seller Rating Performance.

Who should be accountable for inventory management effectiveness?

It’s an all hands on deck approach when it comes to inventory management effectiveness. Several teams are responsible for different pieces of the pie.

The purchasing team is accountable for making sure they are not over or under purchasing, and are closely monitoring each purchase order.

The merchandising team is tasked to ensure the inventory is properly listed, promoted, and priced to move.

The warehouse team, warehouse manager, and inventory specialists are responsible for handling all inventory from FIFO to delegating proper stock levels in each location. This ensures less shelf wear on packaging.

The warehouse team is also accountable for the obvious inventory management tasks – managing proper receiving, correct picks, and correct shipments to create an ease of movement throughout the pick/pack/ship process.

How do you determine if your inventory manager is spread too thin?

There’s a few alarming signs around a warehouse that signal your inventory manager cannot do their job properly. And they all have to do with improper inventory management.

Here are a few signs:

- You have undersold inventory; meaning, there’s a hot item somewhere hidden in the backstock you didn’t list in time for the season.

- Inventory levels are creeping up, but aren’t in line with sales levels. This is a sign of dead stock.

- The amount of shelf wear on packages forces you to mark down the price. This is a result of stocking inventory incorrectly or sitting too long and becoming dead stock.

- The inventory manager is still using a manual spreadsheet. This method of inventory management leads to huge amounts of manual error like mis-shipments and mis-picks.

What should determine ordering frequency?

Reporting, reporting, reporting.

It can’t be stressed enough how important reports are to inventory management processes during peak season.

Historical sales reports from peak seasons past, and throughout the current year, should be used to determine order frequency during peak season. Look back on what you sold the most and the least in tandem with what items are popular this year to make more accurate purchasing decisions.

Sales reports can be broken down by sales channels so you get a better understanding of what items sold on each channel. This gives you a clear idea of the kind of order demand to expect and right order frequency to establish.

How should I prepare for peak seasons?

Peak season for a business is arguably the most important time of the year. It’s the time of year when most businesses make the bulk of their revenue, so it’s pivotal that you have proper inventory management in place in order to succeed.

If you’re heading into your first peak season, here’s what you can do to prepare.

- Conduct a cycle count to make sure all inventory levels are correct.

- Ensure shipping supplies are properly stocked and ready to use. By the way, shipping supplies should be inventoried as well.

- Hire temporary staff to account for a higher demand in orders.

- Utilize history reports to make sure you’ve ordered the right amount of inventory.

- Make sure all inventory, including backstock and picking, is in the proper locations.

Train Your Staff

Theft isn’t the only way by which an employee can harm your business. In fact, some of them may do so simply by not being trained enough.

As a wholesale distributor, it is imperative that your team be characterized not by size but by skill. Digital transformation calls for adaptability within your business. You have probably made the choice to move to an inventory management system, but do the key personnel in your team understand how it works? Further, are they in a position to train their respective teams to work with the system?

Another aspect of staffing in wholesale distribution is the number of contract workers you may have. Market estimates stand at 40% of the total workforce. In other words, nearly half of your employees from security personnel to warehouse staff are in flux all the time.

Do you have training programs and Standard Operating Procedures in place to help guide these people?

It matters that the people handling your stock and keeping an eye on it see the bigger picture as clearly as you do.

Top most festival Products FMCG consumers search today

World Wide Festive Trends Decoded What Indian festive consumers seek...

Read MoreHow right selection of FMCG Salesmen improves brand market share

How can FMCG Companies improve salesman’s technique in order to...

Read MoreHow most searched Fmcg sales and marketing words help newbie salesman

Why undestand FMCG sales management? Sales management is the process...

Read MoreHow Successful FMCG Salesman Starts his Day, a guide

How does one become a good sales executive in the...

Read More