How Inventory of Fmcg goods Helps everyone Predict an awesome Future in business?

What is inventory in FMCG?How Can Retail Firms Increase Their Sales Through Inventory Control?

Definition of Inventory

Inventory refers to the total number of items, goods or materials that a company has in stock. Various types of companies keep inventory. These include restaurants, retail stores and manufacturing companies. The type of inventory a company keeps varies and depends primarily on the nature of its business. For example, a restaurant’s inventory will include food items and food supplies. A retail store’s inventory might consist of shoes, clothing and accessories.

Inventory Management

Companies typically use computer spreadsheets to keep inventory records. Proper inventory management is essential to avoid a product surplus or shortage. The individual responsible for overseeing the company’s stock or inventory must keep track of the current inventory.

This includes tracking product sales and receipts and the shipment of new products. Stock rotation is also a crucial process in inventory management. This involves moving older items to the front of a store or shelf to increase visibility and ultimately sell the product quicker.

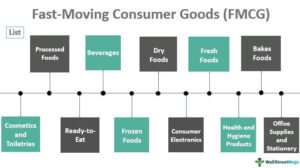

Fast-moving consumer goods (FMCG) are products that are sold in a very short span of time at low-cost and are high in-demand. These products have a high consumption rate with consumers. FMCG covers beverages, food products, household products, cosmetics (oral care, skincare, and hair care), toiletries, dairy products, bakery products, tobacco products, and natural products. FMCG is the 4th largest sector that contributes to the GDP of India, growing from 57.75 billion US$ in 2017-18 to 103.7 billion US$ by 2022.

These products have a high volume of movement of goods in the market as they are frequently purchased by consumers. To facilitate the purchase of these products a well-designed downstream supply chain network is needed in the growing Indian market. Structured supply chain reduces operation cost, improves customer accessibility, and increase the return of investment (ROI).

Supply chain logistics has a vital role in managing the supply and demand for providing efficient and effective delivery. Possessing the entire synergy of goods movement, supply chain logistics has become the fundamental focus of any business. The key objectives of a growing business are optimizing and re-engineering inventory management for effective maintenance of local inventories to reduce the delivery times. The empirical needs of optimizing the finished goods

inventory add value to the business providing a competitive advantage.

Need for inventory management.

Finished goods inventories are the current assets in the statement of financial position of any firm. Post GST the warehouse can be consolidated as there is no longer a need for a warehouse in respective states. The input tax credit is applicable only when products leave the warehouse. As a result, maintaining and managing optimal inventory becomes more crucial.

Indian manufacturers are struggling with challenges in cost of inventory, demand management and process standardization as their market is very diverse.

Lean supply chain management (LSCM) helps in formulating the finished

goods inventory by observing the oscillations from the demand. Such alignment is brought by cost and waste reduction, process standardization, and adaptation to industrial standards. Efficiency of an inventory handling increases with LSCM by Lean shop floor practices is achieved.

Retail businesses rely on sales to earn revenue and increase profits. These companies purchase merchandise and resell it to customers. Inventory control involves considering which items to buy and the quantity of each. Styles change, and so do customer tastes. The company needs to anticipate the amount of sales it can make at a profitable price. When the inventory becomes obsolete, the company can no longer sell it profitably and loses money. Retail firms increase their total sales when they use effective inventory control.

How inventory management helps improve Fmcg Sales? Why Is Inventory Control Important?

India remains to be a potential market for the Fast-Moving Consumer Goods (FMCG) due to its high population. These goods have high volume and cycles of sales with the customers. Consumption of consumer goods has grown to 57.75 billion US$ in 2017-18 from 31.6 billion US$ in 2011 and is expected to grow to 103.7 billion US$ by 2022.

The market is segmented into three segments as follows:

Food and beverages account for 19%,

Health care for 31%,

Household and personal care for 50%

Accommodating 55% of urban market share and 45% of the rural market in India is a mental jigsaw. On comparison of the north Indian markets to south Indian FMCG’s, the marketplace on the north has local producers as well the organised companies with smooth goods movement. But in order to penetrate the south Indian market, companies preferably go with the Mergers & Acquisition strategy

However, the market is hard to penetrate, south Indian FMCG market has the ‘higher per capita consumption’, says Kurush Gant, Executive director, FMCG business.

Consumer package goods or FMCG has the maximum number of sales in a

given period of time. There exist various methods to manage their inventory.

RFID (Radio-frequency identification) is state-of-art technologies that enhance the visibility of downstream supply.For their ability to reduce the bullwhip effect (the phenomenon of increase in the amplification of demand from retail end to the distributor end), maintaining buffer levels of inventory can be considered as a form of lean inventory management.

Effective inventory management is key skills that business today needs to master to increase the performance and efficiency of SC. Such parameter

(inventory control) is influenced by various factors and size of the firm.

Safety stock, speculated stock, pipe-line or in-transit stock and distribution behavior. Where all these are internal factors. The major external factors are customer behavior, external demand, market size and brand analysis . Stockout is external factors that affect the performance of the business, which is caused by paying low attention towards external demand and market size. Market size

and external demand are equal and competitive forces in deciding the

inventory holding in the warehouse.

Why Is Inventory Control Important?

If your business requires maintaining an inventory, you might sometimes feel like you’re walking a tightrope. Not having enough inventory means you run the risk of losing sales, while having too much inventory is costly in more ways than one. That’s why having an efficient inventory control system is so important.

Tip

Not having enough inventory means you run the risk of losing sales, while having too much inventory is costly in more ways than one.

Avoiding Item Stockouts

One of the worst things you can do in business is to turn away customers – people who are ready to give you their money – because you’ve run out of the item they want. “Stockouts” not only cost you money from missed sales, they can also make you lose customers for good, as people resolve to take their business somewhere that can satisfy their needs. An efficient inventory control system tracks how much product you have in stock and forecasts how long your supplies will last based on sales activity. This allows you to place orders far enough ahead of time to prevent stockouts.

Inventory Overstock Hazards

When inventory isn’t managed well, you can also wind up with overstock – too much of certain items. Overstock comes with its own set of problems. The longer an item sits unsold in inventory, the greater the chance it will never sell at all, meaning you’ll have to write it off, or at least discount it deeply.

Products go out of style or become obsolete. Perishable items spoil. Items that linger in storage get damaged or stolen. And excessive inventory has to be stored, counted and handled, which can add ongoing costs.

Working Capital Issues

Inventory is expensive to acquire. When you pay, say, $15 for an item from a supplier, you do so with the expectation that you will soon sell the item for a higher price, allowing you to recoup the cost plus some profit. As long as the item sits on the shelf, though, its value is locked up in inventory. That’s $15 you can’t use elsewhere in your business.

So inventory control isn’t just about managing the “stuff” going in and out of your company; it’s also about managing your working capital, keeping you from having too much precious cash tied up in operations.

Manufacturers’ Inventory Management

Inventory control isn’t just a concern for companies that deal in finished goods, such as retailers and wholesalers. It’s also critical for manufacturers, who maintain three types of inventory: raw materials, works in process and finished goods. If you run out of an essential ingredient or component, production will halt, which can be extremely costly. If you don’t have a supply of finished goods on hand to fill orders at they come in, you risk losing customers. Staying on top of inventory is essential if you’re to keep the line running and keep products moving out the door.

Reduce Oversupply

One way to use inventory control for increasing sales involves not purchasing more inventory than necessary. Purchasing too many items leads to excessive inventory levels. As consumers purchase newer versions of the products, the company sells its remaining inventory at reduced prices. The company loses money by selling the products at the reduced prices. With effective inventory control, the company reduces the amount of inventory it needs to sell at reduced prices.

Create Demand

Another way of using inventory control to increase sales involves creating demand by acquiring a limited quantity of a product. By offering a limited supply of items, the company creates an increased demand among consumers. Each customer wants to purchase the item before the company runs out. The company can charge a higher price for the item because of the higher demand. This increases the company’s total sales.

Reduce Shortages

Inventory control involves balancing between purchasing too many products and purchasing too few. A company can increase sales by ensuring that it maintains enough products in inventory to fill customer orders. When the company maintains a smaller inventory level, it runs the risk of shortages for customers. Those customers often shop at competitor stores, and the company loses its sale. As long as the company maintains enough inventory items to fill customer orders, it records the sales.

Increase Complementary Sales

Companies can also increase sales by maintaining a sufficient level of complementary products in inventory. For example, a retail store that sells vacuums should keep a supply of vacuum cleaner bags in inventory. Customers who purchase the vacuums also purchase vacuum cleaner bags.

Reasons for Inventory Control

According to the Service Corps of Retired Executives (SCORE), inventory costs result in 45 to 90 percent of all business expenses. Therefore, properly controlling your company’s inventory is an essential component to the success of your small business. Carrying excess inventory results in an additional expense for your business, which reduces your bottom line. Not carrying enough of the right products causes lost sales and gives customers the impression that your business is poorly managed.

Maximizing Space

As a small business owner, you probably have limited storage space in your business location. According to SCORE, inventory control allows you to maximize your space by identifying the faster and slower sellers in your product mix. As a result, you can provide for space for better sellers while weeding out slow-moving items.

Room for New Merchandise

In a competitive business environment, being the first to carry the newest products on the market gives you an edge over your competitors. By effectively managing and controlling your inventory, you’re continuously eliminating the outdated and obsolete products in your mix, which means you’ll always have room for the newest, latest thing. Customers will look to your business first when searching for new items.

Turning Over Stock

SCORE also indicates that proper inventory control ensures increased speed in turning over your stock. This reduces the costs associated with carrying excess inventory and keeps merchandise moving through your operation instead of collecting dust in your stockroom. As a result, you’ll run a leaner, more efficient operation, which can lead to higher profits.

Discontinuing Merchandise

According to SmallBusinessTown.com, by controlling your inventory, you’ll know when it’s time to remove an item from your product mix. Perhaps an item only sells well on a seasonal basis, or no longer meets the needs of your customers. By removing the item from your shelf or stockroom and displaying it at a reduced price, you’ll generate some revenue while getting rid of a slow seller.

Avoiding Lost Sales

Just as carrying too much inventory can lead to higher expenses for your business, not carrying enough of the right products can also pose a problem. If you don’t control your inventory, you run the risk of missing out on sales due to running out of a key item. If customers can’t find what they’re looking for at your business, they’ll probably go someplace else. They may even decide not to patronize your business in the future.

How does inventory management help predict the future of a SKU in a brand portfolio ?

The Advantages of Low Inventory Levels.

Maintaining low inventory levels is a common logistics and inventory objective for companies. Inventory requires management and incurs costs. Companies typically try to achieve a balance whereby they have just enough inventory to meet current and near-term demand, but not so much that they have excess.

Reduced Holding Costs

Holding inventory has costs. Typical costs include utilities for the space used and labor costs involved in managing the inventory. A grocer, for instance, may have significantly lower utilities costs by using less freezer or cooler space to store refrigerated and frozen inventory. A distributor or retailer would need less labor to manage a smaller level of inventory holdings than it would to manage higher inventory levels.

Easier Organization

Smaller inventory levels are also easier to manage. It takes less time to organize and retrieve inventory when there is less of it to put away and get out. This makes the process of replenishing short inventory much simpler and more efficient. This is especially important for companies that have high inventory turnover rates and need to quickly get new products onto the shelves.

More Usable Cash

Acquiring inventory is also costly. In industries with high-priced products, it can get very expensive to carry significant levels of inventory. Instead, by maintaining moderate inventory levels and quickly replenishing as needed, your company frees up cash in the short term to meet other expenses and short-term debt obligations. Plus, if you are replenishing inventory in close parallel to selling it, you are bringing in cash at a similar rate to what you pay it out in for inventory.

More Space

Less inventory means more space. Retailers are very concerned with inventory turnover per foot of shelf space. By maintaining lower levels of inventory in each product, they have more room to market and sell more products. Retailers that maintain low inventory levels do not need to allocate as much storage space in the building for extra inventory. This means they have more floor space in which to merchandise and sell products.

How Does Having a Low Inventory Affect Cost?

Achieving profitability is the underlying goal of every small business, which requires generating income in excess of your costs. Businesses can increase profitability by increasing income or by decreasing costs. Companies involved in selling physical goods usually have inventory, which are goods the company keeps on hand that are available for sale. Keeping inventory levels low can have several positive and negative impacts on costs and profitability.

Storage Costs

One of the primary costs associated with inventory is the cost of storing goods before selling them. Businesses may store excess inventory in storage rooms and warehouses, both of which cost money to rent, maintain and manage. Keeping inventory levels low limits the amount of storage space needed for inventory, which can cut down on storage-related costs. For example, a retailer who decides to keep low inventory levels might require less square footage for his store than a competitor who keeps more inventory.

Spoilage and Damage

Another cost associated with keeping inventory is the potential for spoilage, damage and other issues that can destroy inventory or cause it to depreciate. For instance, an electronics retailer who keeps a large inventory of flat-screen TVs might discover that its old inventory drops in value when new TV models are released. Keeping low inventory levels reduces costs associated with the depreciation of inventory.

Shipping Costs

Low inventory levels can potentially be costly to businesses due to shipping costs and other logistical and organizational costs. For example, if a company is about to run out of a high-demand product, it might have to pay a premium for fast shipping to make sure that it has enough inventory to meet demand. Companies with low inventory levels need to monitor the levels closely to ensure that there is enough stock to avoid running out of inventory.

Considerations

Keeping inventory levels low can reduce certain costs, but it also increases the risk of running out of a product. Companies that run out of products may miss out on sales that they would have been able to make had they kept more goods on hand. That said, if a company has too much of its money tied up in inventory, it might not have much cash left over to spend on current expenses and make investments.

The Disadvantages of Holding Too Much Inventory on Hand

Reduces Available Cash Flow

The more money you have tied up in inventory, the less you’ll have to cover essential daily expenses such as rent and payroll. You might be able to get better prices on inventory by buying in volume, and your production may be more efficient when you produce more inventory and achieve economies of scale.

But cash-flow shortfalls can easily wipe out these advantages. If you end up short of cash, you might need to borrow money, and then you’ll need to pay interest and finance charges just to make ends meet. And if you then become short on capital because you’ve spent it all on excess inventory, you might then be unable to take advantage of opportunities that require capital outlay.

Shifting Customer Demand

The inventory you have on hand today may not be the inventory your customers want tomorrow. There’s no way to forecast demand with complete accuracy, because tastes and circumstances constantly change. Clothing goes out of style and economic climates shift, making customers more likely to buy pricier or less-costly items, depending on the economy. Innovations render established products obsolete, such as you can see with the example of digital photography that has put a very serious dent in the 35mm-film industry.

The more inventory you have on hand, the more you’re likely to lose when your customers no longer want what you have.

Inventory Takes Up Space

The more inventory you have, the more you must store. If your storage space is limited, you may find it difficult to find space for items you need because you’ve purchased other products in volume. With perishable inventory that needs to be rotated, if you have more inventory than you can manage, it will be more difficult to keep track of dates. Handling excess inventory takes additional labor hours, which can cancel out the savings you get with volume discounts.

Striking a Balance

Of course, it’s also a disadvantage to not have enough inventory and to not have what your customers need – when they need it. Successful inventory is a matter of finding the sweet spot between having what your customers want, when they want it, but not having so much that it costs you additional money to manage it or reduce it for clearance.

Inventory Control Guidelines

Inventory control is a delicate balance of carrying the optimal amount of inventory. Carry too little inventory, and you risk not having enough goods on hand to meet your customer’s demands. Carry too much inventory, and you risk tying up your money and hurting your cash flow. Establishing inventory control guidelines helps you keep track of your inventory inflows and outflows. You can identify which inventory items sell quickly and which ones stay on your shelves for too long. You can adjust your inventory buying habits so you keep less on hand while still meeting your customer needs.

Frequent Inventory Counts

Inventory control starts with knowing how much of each item you already have on hand. You can make the counting easier by grouping similar items together in your storeroom or warehouse. Have your employees take an accurate count of your inventory items. Look for counting errors that could result in an incorrect inventory count. Make frequent counts to better gauge your inventory flow. Compare the actual count with your book count and make the adjustments so that your book count reflects the actual inventory on hand.

Control Purchase Costs

Keeping your inventory costs low is more than just buying from the cheapest supplier. It also includes handling costs, return and restocking charges, and added shipping or freight costs. Another overlooked aspect is the supplier’s on-time delivery history. Buying from a vendor that always delivers your orders on time eliminates the need to keep large supplies on hand. By considering all the factors, you may find that switching to a more efficient supplier lowers your total inventory purchase costs.

Eliminate Excess Inventory

Inventory that sits gathering dust on your shelves or growing obsolete in a warehouse drains your business profits. Investigate if the cause of your excess inventory stems from placing orders out of habit or if sales have slowed. If you routinely place inventory orders, cut back or eliminate any new orders until you sell your backlogged items. If sales are slow and you have other outlets, consider selling the inventory at another store. If you have customers who previously purchased your overstocked inventory, let them know you have a supply on hand and are willing to make a deal.

Set Reorder Limits

You can avoid being under- or overstocked on inventory items by establishing maximum and minimum reorder limits. The maximum limit is the greatest amount of an inventory item you keep on hand that meets your customer needs without becoming overstocked. The minimum limit is the point where your supply becomes so low that you must reorder or risk running out. You can analyze your past sales to set your maximum and minimum reorder points. Adjust these limits based on seasonal demands and changes in customer ordering and purchasing habits.

Advantages & Disadvantages of Just-in-Time Inventory

Just-in-time inventory management works by keeping stock levels low; you order just what you need, as closely as possible to when you need it. This approach to inventory management is an essential element in the philosophy of lean manufacturing, which is based on using information and strategy to run a business as efficiently as possible.

Advantage: Cash Flow Management

Just-in-time inventory helps you to manage cash flow. When you stock up and buy inventory in bulk, you may get better prices, but you’re likely to buy more than you need for your present purposes. Your working capital will then be tied up in materials that just sit on the shelf for the foreseeable future and you may not have the cash you need for day-to-day expenses such as rent and payroll.

Advantage: Reduces Clutter and Waste

Just-in-time inventory reduces the clutter that is an inevitable result of keeping too much stock on hand. With reduced clutter, you’ll have space to operate more efficiently. Just-in-time inventory management also reduces waste because the farther out you predict demand and purchase inventory, the greater the likelihood you’ll buy items that won’t be used. Customer tastes shift, products are discontinued and stock can deteriorate in storage, especially if it is perishable. Buying just what you need for present purposes helps you to sync more accurately with demand.

Disadvantage: Requires Thought and Strategy

If you cut it close on inventory purchasing, you may be unable to take advantage of an exciting unexpected opportunity because you have insufficient stock on hand and it’ll take too long to get the parts you need. Because just-in-time inventory cuts it close on purchasing, it increases the likelihood of running out of items and losing sales. If a manufacturer doesn’t have sufficient quantity of an item you need, you won’t have much time to find an alternative. Just-in-time inventory requires more thought and strategy than traditional inventory management.

Proactive Management Helps

Many of the disadvantages of just-in-time inventory management can be tempered with finesse and careful planning. Develop relationships with suppliers who can get you the parts you need as quickly as possible. Create systems that provide the most current possible information about what you have in stock, so you can make sure you always reorder on time. Inventory records should be updated every time a part is used or a piece of merchandise is sold, and should also indicate the critical points at which your inventory will drop too low and you’ll lose money due to missed sales.

Factors That Can Lead to Poor Inventory Control

A challenge faced by many small business owners is the maintenance of a proper product inventory. Unlike large chains, small businesses rarely have the luxury of abundant storage space, so owners must be vigilant to ensure they don’t run out of key items or carry too much inventory. Business owners should also be aware of factors that can lead to poor inventory control.

Failure to Plan

A failure to plan can lead to poor inventory control, especially in seasonal businesses. For example, a gift shop that does not order merchandise far enough in advance for the Christmas season may find itself without key products during a critical sales period. Another planning error is to not make an effort to get rid of older or slow-moving merchandise to make room for new products.

Failure to Keep Track

Small businesses that don’t use computerized inventory tracking methods may not always take necessary steps to manage inventory levels. Walking the aisles each morning to perform a visual inspection, keeping track of items sold by using tick sheets or saving portions of price tags can be effective inventory tracking methods, but these actions must be done by all employees on a consistent basis to be of any real benefit.

Buying Too Much

A small business may be tempted to take advantage of a special price on an item by purchasing it in bulk. However, if there is limited storage space or the item doesn’t sell rapidly, any cost savings can be more than offset by the additional costs of carrying the excess inventory. When purchasing in bulk, the business owner needs to be sure she can display the item for maximum sales appeal as well as offer special pricing.

Failure to Monitor Vendors

Some business owners may rely on outside vendors to stock and reorder products, such as potato chip vendors who order and transport their own products and stock them in retail stores for sale. This saves the business time and labor costs. However, if the owner does not monitor the vendor’s orders properly, it could result in excess inventory or loss due to shrinkage, which is loss of inventory due to factors such as theft, miscounting or paperwork errors. The vendor also may not be doing a good job of rotating products on the shelf or removing outdated merchandise.

Not Keeping Up with Trends

Small business owners who don’t keep up with changes in the marketplace can find themselves sitting on obsolete merchandise that no longer meets the needs of customers. They may also miss out on sales by not carrying the “latest thing.” Businesses such as small electronics stores need to constantly evaluate their product mix to keep up with rapid changes in technology.

What is supply chain management in Fmcg industry?How Does Improving Supply Chain Management Increase the ROA or Return on Assets?

Supply chain Analytics: In FMCG, the supply chain is one of the crucial parts of the business. One way that FMCGs are using big data in supply chain analytics is to optimize delivery networks. Organizations across the sector have been using analytics to merge multiple delivery networks to create a faster, more streamlined process. This not only helps to enhance service accuracy, but it also removes the tedious wait times between stations. Furthermore, having big data analytics in FMCG industry can create a more efficient supply chain through leading on the management of warehouses. Thanks to advances in technology, analysis of warehouse facilities and processes can be carried out in real-time. This includes identifying delivery mismatches, inventory levels, and income deliveries.

Minimize Stockouts

Effective vendor management and collaboration

Agile demand fulfillment

Reverse logistics diagnostics and improvements

Return on assets, or ROA, is a fundamental gauge of efficiency, measuring how well your business is using its assets to generate profit. Supply chain management, meanwhile, is all about improving efficiency — gaining a competitive advantage by streamlining the way you get products into your company and then out to your customers. Improving supply chain management boosts ROA through its effect on both profit and assets.

ROA Formula

The basic formula for return on assets is as follows: ROA = Profit / Total Assets. If you have profit of, say, $50,000, and $400,000 in total assets, then your ROA is 0.125 — or 12.5 cents of profit for every $1 of assets. From the formula, you can see that if you generate more profit with the same amount of assets, ROA will rise. If you can produce the same profit with fewer assets, then ROA will rise, too. Even if assets and profit both grow, as long as profit rises at a faster rate than assets, your ROA will increase.

Inventory Control

For a small business, the biggest benefit of effective supply chain management is inventory and order control. You want to always have enough product on hand and in the delivery pipeline to satisfy demand. Selling out of a product — a “stockout” — means turning away customers. So eliminating stockouts boosts revenue, which in turn boosts profits. At the same time, you don’t want to carry more inventory than necessary. Excess inventory is expensive to store, requires more labor to manage and increases the chances of having to write off goods that spoil or become obsolete while in your stock. Eliminating excess inventory reduces costs, and that, too, boosts profits. Higher profits, higher ROA.

Quality and Costs

Supply chain management isn’t just about moving products around; it’s also about monitoring the quality and costs of the products you’re offering your customers. It means identifying and developing relationships with suppliers who offer higher quality at comparatively low prices. Having better products available generates more revenue, boosts customer loyalty (meaning more repeat business) and reduces customer service costs. And lowering your wholesale costs further increases your profit margin, adding even more to ROA.

Assets

The assets portion of the ROA formula also feels the effects of good supply chain management. Inventory is an asset, so the less excess inventory you have sitting around unsold, the lower your total assets and the higher your ROA. Inventory also requires fixed assets to manage — warehouse space, transportation equipment and so on. Effective inventory control can reduce your need for these fixed assets and thus increase ROA. Reviewing your supply chain expenses might even reveal that you could save money by outsourcing some inventory management tasks — for example, allowing your vendors to handle the work of stocking shelves and ensuring adequate supply. In addition to boosting profit, this could allow you to reduce assets by disposing of fixed assets, increasing ROA in two ways at once.

What are the methods of competitive analysis used in the global Fmcg industry? How does data analysis help increase sales in Fmcg sector?

Presently, FMCG organizations have an opportunity to revamp their marketing and operations. Having data analytics techniques in place, FMCG companies can move beyond simple reactive operations and take proactive decisions.

Numerous factors such as – (marketing, inventory, seasonal changes, returns, out-of-stock, raw material availability, localized pricing, and so on) drive the FMCG industry. In these unstable times, the FMCG industry can depend on data analytics to identify trends, gaps, and opportunities in customer behavior and supply chains.

Forecast Optimization: Organizations need to forecast sales to trickle-down effect across departments. The process of generating a forecast needs combining FMCG analytics with business and product knowledge, as well as a continuous focus on improving results to keep up as the business evolves. With leading analytical capacities in place, companies can approach each problem from the different angles required—from the product perspective, customer perspective, retail structure and complexity, and supply chain interdependencies.

Analytics-driven outcomes include:

Build knowledge of product group behaviors based on historical tendencies.

Understand the effect of product forecast

Understand the forecasting accuracy leading to reductions in excess inventory, better manpower utilization, lower expedite costs, and reduced stock-outs.

Price and promotion analytics: With such large investments in trade promotion processes, FMCG companies find it challenging to make informed decisions that trigger appropriate actions and equip them to win in both emerging and developed markets. In such scenarios, FMCG Analytics can help manufacturers become more sophisticated in managing pricing across the value chain. This would include shelf-based pricing, price to distributor and price to the retailer as well as optimization of promotional spend-a massive expenditure for CPG companies.

Analytics-led outcomes include:

Balance the sales and marketing investment mix to increase sales.

Enable control and visibility on trade spend investment.

Improve sales and demand forecast accuracy

Leveraging analytics to increase Customer Retention and Loyalty: In an increasingly hyper-competitive market, the ability to retain customers and gain their loyalty can determine whether a business succeeds or fails. Organizations are turning to data analytics to retain the valuable customers they already have by avoiding weak points. Companies can analyze customer behavior and experience, taking advantage of key opportunities to improve influence buying behavior, customer experience, and increase customer retention.

Product Recommendations

Timely promotions and offers to retain or upsell customers

Engagement and gamification

Data management and efficient and transport reporting of the various fraud incidents results in improved fraud risk management processes. Moreover, the FMCG industries use integration as well as the correlation of data throughout the enterprise. This data helps offer a unified idea of fraud across different business lines, transactions, and products. Besides, data analytics provide accurate fraud trend analysis, the anticipation of any upcoming future modus operandi.

Helps to deliver relevant products

It is important to understand that the products are like oxygen for any organization and the biggest investment for every industry. FMCG industries appoint product management teams who use various data analytics methods. Their role is to find out the new trends, which helps drive strategic maps to bring out innovation, services, and features. Data collation using third party sources combined with analytics helps the FMCG industries to stay in the competition, especially when demand changes or new technology develops.

Brings innovations

Innovation is the only way towards bringing success, and with data analytics, you can get a rough idea of the upcoming trends in consumer behavior. Once you understand the trend, you will be able to make futuristic inventions. Thus, the FMCG industries manufacture products and make services to put them on top of the industry. These innovations are effective enough to maintain a sharp edge advantage over the competitors.

As FMCG industries have to face huge competition, data analytics helps in understanding the market. Also, it helps about what new trends can keep companies ahead of their competitors. The best thing about these innovations is that they are easy to patent and getting the best from them.

Lowers the operation cost

Data analytics are quite useful for the FMCG industries since the only target of the industries is to run the business smoothly. With modern data analytic methods, it is easy to find out various business sectors utilizing unnecessary finances. Hence, data analytics are transforming FMCG industries following these parameters. Almost every sector of the FMCG industry utilizes the benefits of data analytics.

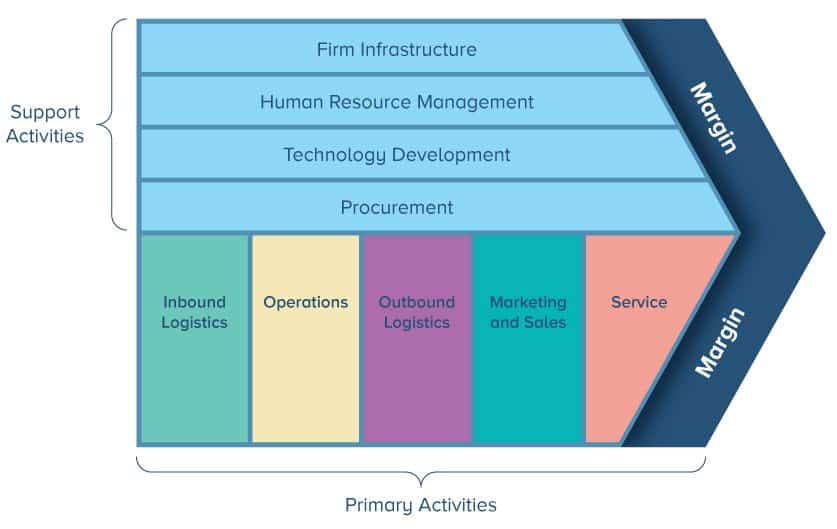

What Is Value Chain Analysis? Porter’s Concept of Value Chain Analysis

Value chain analysis focuses on analyzing the internal activities of a business in an effort to understand costs, locate the activities that add the most value, and differentiate from the competition. To develop an analysis, Porter’s model outlines primary business functions as the basic areas and activities of inbound logistics, operations, outbound logistics, marketing and sales, and service. The model also identifies the discrete tasks found in the important support activities of firm infrastructure, human resources management, technology, and procurement.

The overall goal of value chain analysis it to identify areas and activities that will benefit from change in order to improve profitability and efficiency. For more on Porter’s value chain model and a detailed description of the goals, functions, and tasks of a value chain, read The Art of Value Chain Analysis. Here you will learn about Porter’s primary and supporting value chain activities and how to apply value chain analysis to your business.

What are the Cost Drivers of Value Chain Analysis?

Cost advantage results from a reduction in costs associated with activities in a value chain. After the value chain has been defined, it’s important to associate costs to the activities and then make adjustments for efficiency. Porter’s 10 cost drivers are factors that can impact the cost of an activity. An organization can aim to control these cost drivers in order to improve efficiency, add value, and differentiate.

- Economies of scale

- Learning and spillovers

- Pattern of capacity utilization

- Linkages

- Interrelationships

- Integration

- Timing

- Organization policies

- Location and Institutional factors

Value chain analysis is more than a straightforward cost-to-profit model. It expands on the principles of economies of scale and capacity. There are limits to lowering costs and increasing capacity that can inhibit business growth. Value chain analysis stresses that competitive differentiation can also focus on the perceived value to the customer that justifies a product’s price tag. Finding these perceived values could mean the difference between getting a consumer to spend three dollars on a cup of Starbuck’s coffee rather than one dollar on a competitor’s discount brand.

Examples of Value Chain Analysis by Industry

Food and Beverage: Selecting and sourcing high-quality coffee beans, developing loyalty through excellent customer service, and aggressively marketing their brand were key elements in Starbucks’ creation of a unique identity and a robust competitive edge. Rather than focusing on premium pricing, Pizza Hut outpaced the competition by offering fast delivery of a less expensive product.

Delivery Service: To increase market share and brand loyalty, FedEx’s value chain emphasizes and invests in employee development through excellent human resources initiatives and infrastructure improvements.

Retail: Walmart is constantly performing value chain analysis in order to keep costs low for their customers. From regularly evaluating suppliers and integrating in-store and online shopping experiences to remaining innovative in order to differentiate, Walmart is driven by their commitment to helping people save money.

Implementing and Using Value Chain Analysis

Identifying primary and supporting activities

Rating the importance of each activity in providing value to the product or service

Identifying the cost drivers that cause a change in the activity cost

Identifying linkages and dependencies

Identifying cost reduction and value improvement opportunities

Approaches with a focus on finding differentiation include:

Identifying activities that create value for your customers

Identifying differentiation activities that improve customer value

Identifying the best opportunity for differentiation

Value chain analysis as a tool also concentrates on finding activity links or, as Porter called them, bridges between both the primary and secondary functions of a department, business unit, or enterprise. Although the model is clear in defining general, discrete functions, there are numerous areas of interactions and cross-functionality that can identify cost opportunities, areas of greater efficiencies, and methods to distinguish a brand.

Factors that can influence the value you provide include finding and utilizing the right people, motivating the team, remaining relevant, incorporating technology, and listening to customer feedback.

When analyzing the value chain, it is important to include many stakeholders, and to study the entire market to find areas for competitive opportunities. It is also vital to provide clarity and information, and to define goals. There are thousands of activities varying in importance in the primary and supporting areas of the chain, and opportunities are discovered through cooperative research and analysis, brainstorming, surveying, and observation.

Today’s Impact on Value Chain Analysis

Many companies manage both physical and virtual value chains. The differences in approaches are best illustrated by comparing the consumer experiences of utilizing the services of a brick and mortar bank and those of online banking. Customer service experiences, infrastructure and technology needs, and personnel and training are a few of the many factors to consider when analyzing and adapting these value chains.

In reimagining the basic value chain, you should also study rapid technological advances. The Consumer Goods Forum Board findings recognize that the consumer is now more involved in product development. And, as society onboards new and unknown technologies, value chains need to be continuously reengineered. Societal questions about increased urbanization, the rapid rise of online shopping, and the changing expectations of the consumer are all considerations as valuable as the cost of raw materials, warehousing, and the delivery of any product or service. As companies adapt the basic value chain to the 21st century, many look at this methodology as a journey of transformation rather than a destination. As such, value chain analysis will continue to be a relevant and useful tool to develop and maintain a sustainable, competitive advantage.

Retailers need to ensure that their real-time inventory systems can survive seasonal peaks, maintain data consistency, and deliver instant results. Redis Enterprise uniquely provides the capabilities to modernize real-time inventory—performance at massive scale, data consistency across channels, and multiple modern data models

Tail Piece

Its now or never to Power real-time inventory systems with peak performance, scale, and availability of a product or service.

Top most festival Products FMCG consumers search today

World Wide Festive Trends Decoded What Indian festive consumers seek...

Read MoreHow right selection of FMCG Salesmen improves brand market share

How can FMCG Companies improve salesman’s technique in order to...

Read MoreHow most searched Fmcg sales and marketing words help newbie salesman

Why undestand FMCG sales management? Sales management is the process...

Read MoreHow Successful FMCG Salesman Starts his Day, a guide

How does one become a good sales executive in the...

Read More

Pingback: New FMCG brands give more margin schemes to block brands