How Best Practices in Cold Storage helps newbie frozen foods business

What is a cold room?

Definition of cold room

A room in which a low temperature is maintained (as for refrigeration)

A cold room is a type of refrigeration chamber or insulated space designed to maintain an artificially generated temperature or range of temperatures. Cold rooms are used for storing temperature-sensitive, perishable items, such as food items and pharmaceutical products like vaccines. Cold rooms can vary in size from very small walk-in rooms to very large warehouse storage.

WHY USE A COLD ROOM?

Cold rooms provide precise temperature control for commercial facilities where consistent, powerful refrigeration or freezing is required. For food or chemical storage, this means long-term temperature regulation for perishable or unstable products, lowered deterioration rates, and peace of mind knowing that items are preserved in the optimal conditions.

For pharmaceuticals, the FDA indicates current best practices for the warehousing of drugs and requires them to be stored “under appropriate conditions of temperature, humidity, and light so that the identity, strength, quality, and purity of the drug products are not affected.” Cold rooms represent one of the above mentioned requirements for cold storage of these products.

Some other benefits of Parameter’s cold rooms include:

- Energy Efficiency – Reduce energy costs for storage of samples and other materials. Cold storage units are constructed to prevent fluctuations in temperature, meaning less energy is required to balance and adjust the temperature while in use. This holds true no matter your industry.

- High Product Standards – Guarantee potency of vaccines, drugs, and other sensitive items with cold storage. This can also help improve your company’s reputation and reliability.

- Safety and Security – Medications and medical equipment are highly sensitive and expensive — ensure their safekeeping with locked, weather-proof cold storage units.

Cold storage is also used in transportation of industrial materials and other temperature-sensitive products across industries. In this case, the container has a cooling unit installed to ensure optimal temperature control. Cold rooms, in general, are valued for their precision and power and can maintain specific temperatures over long periods of time.

HOW DOES A COLD ROOM WORK?

The design behind cold rooms that allows them to function efficiently isn’t so different from any other refrigeration system. Cold rooms use a compressor, condenser, fans, and an evaporator to maintain temperature within the unit. After a gas refrigerant gets compressed in the compressor it expands, and the gas absorbs energy. The hot gas flowing from the compressor passes over the evaporator coils and, after liquifying under high pressure, this cools the evaporator coils and the surrounding air. In order to maintain temperature, cold rooms must also be efficiently insulated.

WHAT IS THE TEMPERATURE RANGE OF A COLD ROOM?

Most cold rooms will be able to accommodate temperatures between -2°C and 10°C. As for the specific temperature range of a cold room, that depends on what’s being stored inside. For food items such as fresh produce, an ideal cold room temperature ranges between 2 and 8 degrees Celsius. Pharmaceutical ICH storage will require a 5°C with a tolerance of ±3°C. When colder conditions are required, freezer rooms will be the preferred option, able to tune down to -30°C for storage of pharmaceutical products or chemicals. Freezers are also able to provide ultra-low storage needs at -50°C to -80°C.

WHAT CAN BE STORED IN A COLD ROOM?

As for their application, cold rooms can be used to store a variety of items across industries. The most common items include biopharmaceutical and pharmaceutical products, textiles, tobacco products, perishable foods, flowers, delicate plants, artworks, and even rare books.

Precise temperature control of certain drugs and medical devices is especially important to prevent material corruption and guarantee usage safety. Laboratory reagents, dialyzers, disinfectant solutions, sterilants, burn treatment products, and dental restorative materials, for example, are all highly temperature sensitive and require routine or consistent refrigeration to be effective. Cold rooms also can be utilized to process or slow down chemical reactions in engineering settings. And as mentioned above, if sensitive materials need to be temperature-regulated during transit, cold rooms can help there too.

What is the difference between cold room and cold storage?

Working in the frozen meat sector, I would say a “cold room” is typically <5C but >0C and is where people are working or sometimes frozen meat is thawing or “tempering” ready for chopping/mincing.

A “cold store” typically operates at temperatures between -4C to +4C and is where finished products are held ready for despatch.

We are one of the biggest users of Nitrogen for freezing in the UK however we do blast freeze some products and the target is to achive <5C in 4 hours.

However cook/chill operations mean that after cooking we reduce the temperature to <8C within 90 minutes, these products are then either sent through the nitrogen tunnel or blast chilled as described above.

Its used more in the frozen veg industry and uses the blast of cold air (-20C) to freeze the food particles “individually” like in frozen peas, so that they don’t clump together.

Used in packing cheese either chilled ( blasted with air at 0C) or frozen, then weighted using a Yomato weighting system before beeing packed in 2kg bags (flushed with nitrogen)

A cold store basically incorporates a reception room, where fresh meat is received and inspected at a controlled room temperature between 8° and 12°C, dispatch and holding rooms at about 2–4 °C, and one or several cold chambers for meat and offal at appropriate storage temperature. It may incorporate a cutting and deboning room at a temperature between 8° and 12°C, a packaging room and a sales room, both with a low temperature and dew point at about 5° to 7°C. For freezing and frozen storage there are freezing tunnels or rooms at temperatures ranging from -30° to -45°C, and frozen storage chambers at a temperature to suit the intended storage period. General requirements are a machine room, offices and cloakroom.

STORAGE TEMPERATURES

The following are storage definitions, as defined in the General Notices section of the United States Pharmacopoeia (USP) XXII-NF XVII, for recommended conditions commonly specified on product labels.

|

French regulatory affairs, concerning the decrease of the temperature.

Beef : One has to decrease the temperature of carcasses as soon as inspectors have checked them – only required to be below 7°C for carcasses before loading, 3°c for variety meat (liver, heart…).

Be very careful concerning the temperature of your cold room (no freezing!), you must decrease it regularly and not strongly – same requirements for beef, chicken, pigs… It’s up to you to set your temperature in order to be ok!

Some high quality of beef meat named ‘label rouge’, you have to be above 10°C about 10 hours after slaughtering (about pH 6), then 7°C max after 36 hours in the tenderloin.

The main variation concerning “chilled” and “frozen” processing / storage. The term “Cold Room” is infinitely flexible . The “room” temperatures required are a result primarily of the microbiological hygiene requirements and (partly) the limitations of people to work at low temperatures.

UK regulations and the encyclopaedic Meat Industry Guide (2006)

The Department of Health has published guidanceon the Food Safety (Temperature Control) Regulations1995 which gives advice on the types of foods which are required to be held under temperature control. It also gives guidance on the circumstances when the Regulations allow some flexibility from the temperature requirements including during food preparation.

The Regulations require that foods which are likely to support the growth of pathogenic micro-organisms or the formation of toxins be held at or below 8 °C (or above 63 °C). Certain tolerances are allowed. Other temperature requirements for product specific foods are

given on page 3. Lower workroom temperatures in premises where particular foodstuffs requiring temperature control are produced, may be justified (see

paragraph 10). (UK – Food safety regs 1995)

“Cold store” means any premises, not being a part of approved meat products premises,

which store unpackaged meat products under refrigerated conditions.

(UK – Meat products Regs 1994)

Cold Store

The cold store is spec’ed to run at 0 – 2 degrees C and is currently configured to hold 180 pallets with opportunity to increase if needed.

(Australia – Commercial advert 2006)

7) Factories producing frozen food should also meet the following requirements:

a. The meat-cutting room should have temperature control equipment and the temperature should not exceed 20 degrees centigrade.

b. There should be suitable rooms respectively for chilling. quickfreezing and cold storage that are connected with the work rooms.

The temperature in the rooms for chilling should be kept between zero and 4 degrees centigrade.

The temperature of the room for quick-freezing should be maintained at -25 degrees centigrade or below. The frozen products cannot leave the room before their central temperature have dropped to -15 degrees centigrade or below (within 48 hours for meat products, 24 hours for poultry meat, and 14 hours for aquatic products).

The temperature of the cold store room should be maintained steadily at -18 degrees centigrade or below and the central temperature of the frozen products should be maintained at -15 degrees centigrade or below.

The cold store room should have automatic temperature recording device and mercury thermometer.

(China, draft 1984)

Suitable refrigeration equipment to enable the internal temperature of fresh meat to be maintained at not more than +7°C for carcases and cuts, +3°C for offal and -12°C for frozen fresh meat, such equipment to have a drainage system which avoids risk of contamination of fresh meat;

(UK – Fresh meat reg 1992)

99.01 Definitions . For the purpose of this chapter’, unless the context otherwise requires :

(1) “Cold storage” means the storage or keeping of articles of food at or below a temperature above zero of 50 degrees Fahrenheit in a cold storage warehouse .

(2) “Cold storage warehouse” means any place artificially cooled to or below a temperature above zero of 50 degrees Fahrenheit, in which articles of food are placed and held for 40 days of more .

(11) “Chill room” means a room or compartment for the chilling of meats which is capable of maintaining temperatures within 2 degrees Fahrenheit plus or minus of 35 degrees above zero Fahrenheit, with a’ tolerance of 10 degrees Fahrenheit for a reasonable time after fresh food is put in for chilling.

(US – 1981)

Food business operators producing … meat preparations … must ensure compliance with the following requirements.

D1. The work on meat must be organised in such a way as to prevent or minimise

contamination. To this end, food business operators must ensure in particular that the

meat used is:

(a) at a temperature of not more than 4°C for poultry, 3°C for offal and 7°C for other

meat; and

(b) brought into the preparation room progressively as needed.

D2. © Immediately after production,… meat preparations must be wrapped or

packaged and be:

(i) chilled to an internal temperature of not more than 4°C; or

(ii) frozen to an internal temperature of not more than -18°C.

These temperature conditions must be maintained during storage and transport.

853/2004 Annex III Section V Hygiene During Cutting & After Production: Chapter III points

(UK – Meat Industry Guide 2006)

Cold Storage Temperatures:

A Guide to Chilling

Abiding by cold storage temperatures is essential to ensure maximum freshness and prevent bacterial spread. With a bit of patience and a commercial cold storage unit, this doesn’t have to be a difficult task.

This guide to chilling takes you through the ins and outs of storing fresh produce and explains why temperature is the key to keeping your foodstuffs safe for customers.

Understanding the Danger Zone

It’s common knowledge that leaving produce at room temperature level can be dangerous because of the threat of bacteria. However, food only has to reach a temperature of 4°C or higher for bacteria to develop.

Even at this low temperature, harmful bacteria will begin to develop within half an hour in produce, which is why it’s so important to chill food immediately. Within four hours, bacteria will have reached critically dangerous levels and could seriously harm someone.

Harmful bacteria can live on foods even after produce is cooked, so it’s not worth the risk if produce has been left unrefrigerated. Not only can bacteria cause a number of illnesses, such as Salmonella and Campylobacter, these bacteria can easily spread throughout a kitchen, infecting other healthy produce and kitchen items.

If you want to avoid the bacteria danger zone, ensure your foods do not reach temperatures of 4°C or above whilst in storage.

Chilling at a Safe Temperature

As 4°C and above is considered dangerous for fresh produce like meat, fish and poultry, it makes sense that anything below this is generally considered safe. Whilst there is no ‘one temperature fits all’ when it comes to chilling food, the lower the temperature the longer produce is likely to last – with some exceptions where certain foods are damaged by low temperatures.

This is why many businesses choose to freeze their food at the recommended temperature of -18°C, rather than keep it chilled. However, if you want to serve fresh, unfrozen produce, anything under 4°C is considered safe.

The easiest way to ensure your produce is chilled at a safe and consistent temperature is with a commercial cold storage unit. Grade A cold stores come with temperature monitoring and recording as standard to allow you to keep your goods at a safe and consistent temperature during their time in storage.

Let CRS help you find a cold storage solution that’s right for you.

Best Practices for Storing Chilled Goods

Keeping your goods in cold storage below 4°C is the most effective way to prevent spoilage but there are some best practices and guidelines you can follow to extend the freshness of your produce.

Be capacity aware

Your cold storage unit will have a maximum capacity and this should be respected if you want it to perform at its best. When stocking your unit, always ensure produce is well spaced so that air can circulate freely. Not doing so can result in temperature dips, which eventually leads to faster produce spoilage.

Quick cooling

If you’re planning on chilling cooked foods, its important cool them as quickly as possible after cooking to minimise the time dishes are spend in the ‘danger zone’. A blast chiller is the quickest and safest way to do this to prevent bacterial development.

Check your temperatures

A temperature monitoring system is essential for any cold storage unit but it is also essential to regularly check and record internal temperatures manually. This allows you to look out for any fluctuations that might damage the quality of produce.

Our Cold storage Temperature Ranges are as follows…

+25 to +60ºC | Incubator Stores / Hot Boxes

+15 to +25ºC | Ambient Storage / Room Temperature

+8 to +15ºC | Cool Storage

+2 to +8ºC | Cold Storage / Chilled Stores

-4 to +2ºC | Refrigerator Storage

-40 to 0ºC | Frozen Storage

-70 to -40ºC | Ultra-Low Storage

Cross contamination

Always avoid storing raw produce with cooked food and fruits/vegetables as this dramatically increases the chances of cross contamination. Raw produce should be well packaged and only stored alongside the same type of product.

E.g. All fish products should be stored together but must also be well separated from all meat products.

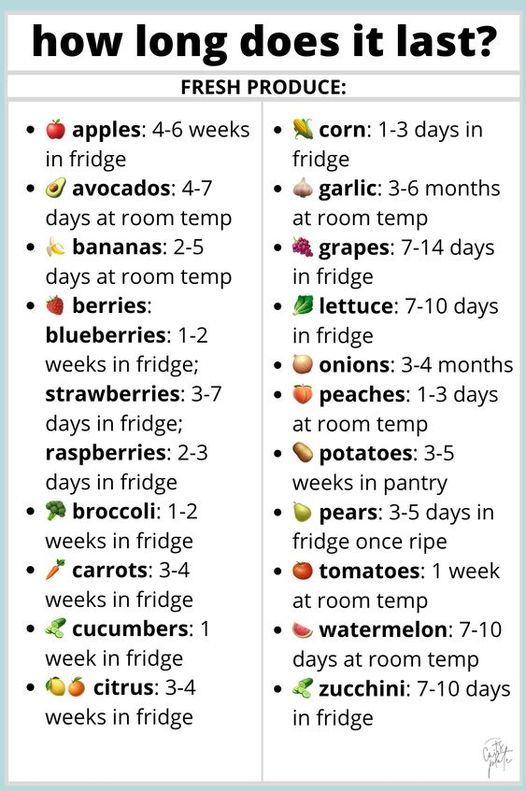

How Long Do Most Chilled Foods Last in Cold Storage?

Not all foods will last the same length of time in cold storage but if your food is chilled to the correct temperature then it should be easy to tell. Even when purchased in bulk, most fresh produce has a use-by date, so be sure to pay attention to that.

Despite this, there are average shelf life times that certain foods typically fall into and some of these can be seen in this graph.

Food Type | Avg. shelf life when stored below 4°C |

Meat (beef, lamb, pork etc.) | 3-5 days |

Cured meats (salami, chorizo, prosciutto etc.) | 2-3 weeks |

Minced meat and offal (liver, heart, kidneys etc.) | 2-3 days |

Poultry | 3 days |

Seafood (prawns, mussels, crab etc.) | 2-3 days |

Fruit juice (orange, cranberry, grape etc.) | 7-14 days |

Cream | 5 days |

Milk (all types) | 5-7 days |

Young Cheese (cream cheeses, cottage, ricotta etc.) | 10 days |

Hard Cheese (cheddar, parmesan etc.) | Anywhere between 1-3 months |

Eggs | 3-6 weeks |

Whilst these shelf life averages can go some way in helping you to understand how fresh your produce is they shouldn’t be taken as a definite. It’s always best to check food carefully before deciding to use it.

Has your Produce Gone Bad?

Concerned your chilled produce might be off? If food has been chilled correctly in temperature controlled cold storage and is still supposedly within its safe use-by date, it’s unlikely to be off. Nonetheless, sometimes a number of variables can lead to premature food deterioration and bacterial development.

Here are a few ways to check:

Sight – Does the produce have a colour that is unusual? Many meats will go grey or can be visibly slimy when off. If you’re produce has started to discolour, even in small areas, it could be harbouring harmful bacteria and should be disposed of.

Smell – Meat and poultry should have little to no odour when fresh, so if there’s an unpleasant smell, it’s definitely no longer safe to consume. Many fish products are the same and should have little to no smell (apart from smoked fish) when fresh. Fish products are usually unsafe when they begin to develop an unusually strong fish odour.

Texture – Texture is very important when determining the freshness of things like fruits and vegetables. If your produce is soft to the touch when it shouldn’t be, then it’s time to throw it out. Even if it looks ok on the outside, an unpleasant texture can signify deterioration and possible bacterial growth, so it isn’t worth the risk.

The most important thing to remember is that if you’re not certain your food is safe then throw it away. It’s not worth risking your customer’s health or the reputation of your business, just remember to learn from your mistakes and follow best practices next time around.

Ambient, “Room Temperature”, “Cold ” – what is what?

Cold room temperature, chartwalk-in cold room temperaturevegetable, cold room temperature

cold room temperature in celsius,cold room temperature for meat,cold room temperature controller

On the outer packaging of pharmaceutical products one often finds labels with storage requirements like for example “ambient”, “room temperature” and “cold chain”. But what do they exactly mean? And do these conditions also apply during transport?

The second question is easy to answer: “The required storage conditions for medicinal products should be maintained during transportation within the defined limits as described by the manufacturers or on the outer packaging.” (EU-GDP Guidelines). But also according to the PIC/S Good Distribution Guide these conditions should be applied also for transportation (see section 9.2.1).

With the first question, it is more difficult. Here, different definitions can be found.

The European Pharmacopoeia (Pharm.Eur.) gives some hints in chapter 1.2 (Other provisions applying to general chapters and monographs) with referring to analytical procedures:

Deep-freeze: below minus 15°C;

Refrigerator: 2°C to 8°C;

Cold or cool: 8°C to 15°C;

Room temperature: 15°C to 25°C.

There are also some definitions in the WHO guidance:

Store frozen: transported within a cold chain and stored at -20°C (4°F).

Store at 2°-8°C (36°-46°F): for heat sensitive products that must not be frozen.

Cool: Store between 8°-15°C (45°-59°F).

Room temperature: Store at 15°-25°C (59°-77°F).

Ambient temperature: Store at the surrounding temperature. This term is not widely used due to significant variation in ambient temperatures. It means “room temperature” or normal storage conditions, which means storage in a dry, clean, well ventilated area at room temperatures between 15° to 25°C (59°-77°F) or up to 30°C, depending on climatic conditions.

And the U.S. Pharmacopeia (USP) has some references:

USP <659> “Packaging and Storage Requirements” gives various examples for different storage conditions, for example:

Cold: Any temperature not exceeding 8°C (46 °F).

Cool: Any temperature between 8° and 15° (46° and 59 °F)

Room temperature: The temperature prevailing in a work area.

Controlled room temperature: The temperature maintained thermostatically that encompasses at the usual and customary working environment of 20°-25° (68°-77 °F). Excursions between 15° and 30° (59° and 86 °F) that are experienced in pharmacies, hospitals, and warehouses, and during shipping are allowed. Provided the mean kinetic temperature does not exceed 25°, transient spikes up to 40° are permitted as long as they do not exceed 24 h. Spikes above 40° may be permitted only if the manufacturer so instructs.

Warm: Any temperature between 30° and 40°C (86° and 104 °F).

Excessive heat: Any temperature above 40° (104 °F).

The Japanese Pharmacopeia (JP) describes temperature for tests or storage as follows:

Cold: 1°C – 15°C

Standard temperature: 20°C

Ordinary temperature: 15°C – 25°C

Room temperature: 1°C – 30°C

Lukewarm: 30°C – 40°C

This is not overall harmonised, as this simple summary shows:

Pharm. Eur. | WHO | USP | JP | |

| Frozen/ deep-freeze | below -15°C | -20°C | – | – |

| Refrigerator | 2°C – 8°C | – | – | – |

| Cold | 8°C – 15°C | 2°C – 8°C | <8°C | 1°C – 15°C |

| Cool | 8°C – 15°C | 8°C – 15°C | 8°C – 15°C | – |

| Room temperature | 15°C – 25°C | 15°C – 25°C | “temperature prevailing in a work area” | 1°C – 30°C |

Controlled room temperature | – | – | 20°C – 25°C | – |

| Ambient temperature | – | 15°C – 25°C or 30°C depending on climatic conditions | – | – |

And then there is the EMA GUIDELINE on DECLARATION OF STORAGE CONDITIONS from 2007, requiring that the storage conditions given in the package leaflet (PL) and the labelling of medicinal products should refer to the stability studies made for the finished product:

Testing conditions where the product is stable | Required labelling statement | Additional labelling statement, where relevant |

| 25°C/60%RH (long term) 40°C/75%RH (accelerated) or 30°C/65%RH (long term) 40°C/75%RH (accelerated) | None (The following PL statement is required: “This medicinal product does not require any special storage conditions”.) | Do not refrigerate or freeze |

| 25°C/60%RH (long term) 30°C/60 or 65%RH (intermediate) or 30°C/65%RH (long term) | Do not store above 30°C or Store below 30°C | Do not refrigerate or freeze |

| 25°C/60%RH (long term) | Do not store above 25°C or Store below 25°C | Do not refrigerate or freeze |

| 5°C ± 3°C (long term) | Store in a refrigerator or store and transport refrigerated | Do not freeze |

| Below zero | Store in a freezer or Store and transport frozen | – |

So as a resume, terms like “ambient”, “room temperature” and “cold chain” should be avoided as the only labelling for storage or transport because they are not always clear and might have different meanings in other parts of the world. Storage conditions are always better explicitly specified in terms of a defined temperature range (e.g., 15°C -25°C or +2°C to +8°C). Particular attention should be given to avoiding freezing of liquids and semi-solids.

WALK-IN COLD ROOMS AND FREEZERS, WHAT’S THE DIFFERENCE?

What’s the difference between a walk-in cold room, and a walk-in freezer?

One’s colder than the other.

It sounds simple enough, but the differences are little more complex in reality, and we get asked this question quite a lot by our customers. So let’s elaborate:

Walk-in cold rooms

Walk-in cold rooms will generally operate in one of two temperature zones:

Temperature zone 1 operates at a temperature between 2C and 12C, and in the industry a cold room that operates at this temperature is often referred to as a “chiller”. This zone is used to store consumables that will be used within a few days.

Temperature zone 2 operates at a temperature between -2C and +5C. This temperature zone is used to store consumables that will be used within a few days to a few weeks and it is preferred where a large stock of fast perishing items need to be kept just below freezing.

There are walk-in cold rooms that operate in only one zone, or both. Ours do both.

Walk-in freezers

Walk-in freezers look identical to walk-in cold rooms from the outside but as you would expect, walk-in freezers can operate at far lower temperatures than walk-in cold rooms.

Walk-in freezers usually have a temperature range of -18C to -22C. -18C is the minimum level at which something is classed as ‘deep freeze’. Walk-in freezers are used to store consumables for months, or even years, at a time and just like cold rooms, walk-in freezers are designed to provide extremely even temperature control, to boost stock longevity.

Which is best for me?

Do you need to freeze things, or keep things cool? If the former, get a walk-in freezer and if the latter, go for a walk-in cold room. If you need to freeze and cool things, unfortunately there isn’t a single solution for both, so you’ll need one unit for each task.

Walk-in cold rooms and walk-in freezers from Icecool Trailers

Your business can benefit from competitive pricing and huge flexibility with our walk-in cold room and walk-in freezer hire solutions. We have an excellent range of units for hire right now, and each of them can be built up on site. This means that they can be installed within even the most challenging of environments.

The sizes we currently have available for both freezer and cold rooms are 1.8M (5 cubic metres) and 3.0M (8.5 cubic metres).

Types of Pallets and uses

The correct distribution and location of the goods greatly facilitates the logistics operations of a warehouse or distribution centre. It is of little or no use to equip an installation with the appropriate industrial storage system if the arrangement of the load hinders the work flow and/or could cause damage to the goods themselves or even cause an accident involving warehouse staff.

Monitoring the unit load is one of the many factors to consider when it comes to safety in warehouses.

Thus, the unit load is a homogeneous grouping of a set of products arranged on a support or platform that facilitates the handling and transfer of goods and that therefore acts as a logistical unit as such.

The unit load can be the product’s own packaging box, a container or a pallet, which is the main support in pallet racking systems as its name indicates, and not intended for picking or medium and/or light loads in cartons.

What is a pallet?

A pallet is a support or platform for boards to stack the load. They are rigid frames on which the goods are placed, distributed in a homogeneous way at height and on the pallet surface. The pallets, and consequently the load, will be transported from one side of the racking or the warehouse to the other by means of forklifts or pallet trucks.

Types of pallet

There are different kinds of pallets, depending on their size, their composition, etc. We list below the main existing pallets and their characteristics.

1) Pallets according to their dimensions:

Europallet:

It is a support whose measurements are 1200×800 mm. It is currently the most widespread in Europe. This type of pallet is regulated by EPAL (European Pallet Association) and as its website indicates, “around 500 million are currently in circulation”.

In addition, it is one of the types of pallets standardized by ISO (International Organization for Standardization). European industry and logistics therefore use the europallet as the main support to facilitate the flow of goods and their grouping in the transport and storage process.

The measurements of the europallet are determined by the width of the truck wagons, containers and trailers, which are usually 2400 mm, which allows them to be placed in a way that takes full advantage of the load space.

Main characteristics:

- Measurements: length 800 mm, with 1200 mm.

- Materials: 11 wooden boards, 9 blocks, 78 nails.

- Approximate weight: 25 kg.

- Safe workload on the move: 1500 kg.

- Static load: when stacking loaded pallets on a solid and even surface, the lowest pallet should not exceed a load of more than 5500 kg.

- They contain various markings for identification, such as the licence number and the treatment method. However, the most visible is the acronym EPAL.

Essential Warehouse and Cold room Vocabulary and Acronyms

And now, here they are—the most common warehouse terms, acronyms, and phrases you’re likely to hear on the job:

3PL: Third-party logistics (see third-party logistics for definition).

Backhaul: The process of moving goods from what was originally their final destination back to their origin point. In warehousing, backhauls can also be truckloads of goods that customers have returned or for which they have requested an exchange. An incoming backhaul will typically need to be inspected for damage and then, once approved for quality, restocked. Learn more about backhauling and reverse logistics.

Back order: A purchase order for an item that is currently out of stock. When a particularly popular item sells quickly, sometimes the warehouse runs out of stock before they get more from the supplier or manufacturer. Retailers will often continue to sell these items to consumers with a note that they are “on backorder” and will be delivered later than normal. When this happens, warehouse teams need to fulfil existing orders as soon as new stock arrives rather than first moving that inventory to storage.

Bar coding: The machine-readable identification system used to track, scan, and process inventory.

Batch picking: A picking process in which a batch of multiple customer orders containing similar items is gathered from warehouse shelves at the same time. For instance, three separate customer orders including a box of pencils could be batched so the picker needs to walk to the pencil-box storage location only one time rather than three. Learn more about warehouse picking processes.

Bill of lading(BOL): An official document detailing items contained in a shipment. The bill of lading moves with a shipment from the sender to the shipper and then to the consignee (final recipient). When a warehouse receives a shipment from a supplier, it comes with a bill of lading that processing clerks use to verify that the delivered goods match the purchase order.

BOL: Bill of lading (see bill of lading for definition).

Cantilever rack: Storage device with prongs rather than shelves that are used to store long and/or oddly shaped items. Cantilever racks may be free-standing or mounted to a wall.

Cold storage: A section of a warehouse in which refrigerated or frozen products are stored. Cold storage is most commonly found in food-grade warehouses.

Cross-docking: A distribution process in which goods are received from a supplier and immediately sorted, packed, and shipped to a customer rather than being moved to a warehouse shelf for storage. Cross-docking is often used in warehouses to fulfill customer orders for items that were on back order.

Cycle count: An auditing process in which inventory is counted on a cyclical basis. Inventory is counted in sections on a regular basis to make auditing more manageable and ensure that inventory records are accurate. To learn more, check out our guide to warehouse auditing.

Dimensional weight (DIM): A measurement used by couriers and shipping carriers to determine the cost of sending goods. To calculate the dimensional weight of a package, you multiply the length times the width times the height.

Dispatching: The process of organizing, scheduling, and managing vehicles and drivers. Warehouses that have an in-house local delivery team often have a fleet dispatcher who coordinates packing, vehicle loading, and delivery scheduling. Learn more about fleet dispatching.

Distribution center: A facility where goods are sorted, packed, and processed for shipping to their final destination (the customers). Many warehouses are also distribution centers, meaning they not only store or warehouse goods but also offer picking, packing, and even delivery services.

Drop tailer: A truck trailer that is dropped off for loading and then picked up at a later time. Sometimes couriers will have a driver drop off an empty trailer and pick up a full one to maximize efficiency.

Dry storage: A section of a warehouse in which products are stored in a nonrefrigerated environment that is at or around 50 degrees Fahrenheit. Dry storage may still be temperature-controlled to combat extreme outdoor weather conditions.

Estimated time of arrival (ETA): The expected time a vehicle or vessel will get to its final destination. Warehouses typically receive an ETA for trucks carrying incoming stock. Warehouses may also need to provide an ETA for delivery of outgoing stock. Learn more about delivery estimates.

Estimated time of departure (ETD): The expected time a vehicle or vessel will leave its point of origin. Warehouses often use this to note when a delivery truck or courier vehicle will be completely loaded and depart a loading bay. Learn more about delivery estimates.

Estimated time of delivery (ETD): The expected time goods will be delivered. Suppliers and manufacturers may supply receiving clerks with an estimated time of delivery instead of an estimated time of arrival for incoming inventory. Learn more about delivery estimates.

ETA: Estimated time of arrival (see estimated time of arrival for definition).

ETD: May indicate “estimated time of departure” or “estimated time of delivery” (see estimated time of departure or estimated time of delivery for definition).

FIFO: First in, first out (see first in, first out for definition).

First in, first out (FIFO): An inventory management strategy based on the principle that the first items into the warehouse should be the first ones to leave. Food warehouses often employ this strategy to ensure that products expiring the soonest are the first to be shipped out.

Forward-pick location: An easily accessible storage area in which small quantities of frequently purchased items are placed. Forward pick locations are used to make picking faster when orders come in. Pickers can quickly access items in the forward pick location and then replenish that supply from a secondary location when it won’t impact customer turnaround times.

Gaylord box: A bulk shipping and storage box sized to fit on top of a pallet. Gaylord boxes are frequently used in the logistics industry to transport and easily store goods of many shapes and sizes.

JIT: Just in time (see just in time for definition).

Just in time (JIT): In warehousing, “just in time” is a supply-chain management method with which products are ordered, stored, assembled, or manufactured to fulfill an order just in time. No matter how skilled you are at calculating demand, you will run into incidents where demand exceeds your supply. Many companies store safety stock, or more stock than their predicted demand requires, to cover them when these demand surges occur. The JIT method of inventory management doesn’t use safety stock to cut down on storage costs.

Last mile delivery: The process of transporting goods from a warehouse or distribution center to their final destination (the customer). Last mile delivery refers exclusively to the final stage of the logistics supply chain (and happens after packing and vehicle loading).

Lead time: The time it takes to complete a logistics process. Lead time for final delivery, for instance, would include the time it takes for picking, packing, vehicle loading, and last mile delivery. The lead time for inventory replenishment includes the time required to fulfill a purchase order, transport goods from supplier to warehouse, inspect the shipment, and then restock that inventory.

Less than truckload (LTL): A type of freight shipping in which goods that weigh more than 150 pounds but take up less than a full truckload are transported. Shipping carriers use LTL shipping to move goods for multiple retailers in the same truckload. Each retailer pays only for the cargo space their items take up.

Lights-out warehouse: A warehouse that employs machines and automated systems to manage and move products rather than human labor.

LTL: Less than truckload (see less than truckload for definition).

Packing: Preparing purchase goods for last mile delivery. Packers put purchased items into boxes and prepare them to be loaded onto delivery vehicles.

Pallet: A flat structure, typically made out of wood, used to move goods. Pallets make is easier to move and store large items (or large quantities of items). They can be easily maneuvered with a forklift, pallet jack, or other machinery.

Pick and pack: A common way to refer to the processes of picking and packing within a warehouse (see picking and packing for definitions).

Pick list: The list of items pickers need to retrieve from warehouse shelves or storage. Customer orders are broken down into lists of purchased items or “pick lists,” which are given to pickers to retrieve.

Picking: The process of gathering or picking purchased items from warehouse shelves. When a customer makes a purchase, pickers gather those purchased items from their storage location and bring them to packers. Learn more about warehouse processes.

PO: Purchase order (see purchase order for definition).

Purchase order (PO): A request for goods sent from a buyer to a seller. Warehouses place purchase orders with suppliers and manufacturers for replenishment when stock runs low.

Put-away: The process of taking inventory from receiving and “putting it away” on shelves or storage racks. Workers may use this term to direct you to put return items on shelves as well.

Radio-frequency identification (RFID): A wireless tracking and data-transfer system. In warehousing, RFID tracking is used to monitor inventory. RFID tracking tags are placed on inventory as it comes in, and sensors throughout the warehouse are able to then track those goods as they are moved throughout the facility.

RFID: Radio-frequency identification (see radio-frequency identification for definition).

Receiving: The warehouse intake process. When goods arrive at a warehouse, they first go through receiving, where they are scanned and inspected by a receiving clerk. Learn more about warehouse processes.

Replenishment: The restocking of inventory. “Restocking” is used differently depending on which warehouse department you work in. Receiving clerks, for example, may refer to goods arriving from a supplier to fulfill a back order as replenishment. Pickers, on the other hand, often use replenishment to refer to stock that needs to be moved from a secondary location to a forward pick location.

Reverse logistics: The process of moving goods backward from what was originally their destination (typically the customer) to their origin point. Reverse logistics is used when a customer returns or exchanges an item. The process of retrieving that returned item from the customer, bringing it back to the warehouse, inspecting it for quality, and then restocking it is reverse logistics.

You pay for what you get

When you hire a freezer or cold room from us, our fully trained personnel will deliver and install the unit for you, and dismantle and take it away when you no longer need it. We supply all of the necessary leads, and all you need is a working mains power supply. If you do not have one of these, then let us know and we’ll hook up a portable generator instead.

What does cold room mean in business?

Here’s what you need to know about cold room business

Cold room business is fast becoming a popular side hustle in Nigeria. There is hardly any household today in the country that does not feed on frozen foods such as yoghurt, ice cream, ice block, soya milk, frozen fish or poultry products.

Many business-minded individuals are now taking advantage of this huge demand to start cold room businesses in order to make quick money.

How to start a cold room business

Decide your scale:

The first step is deciding whether to start on a small scale or on a large scale and this largely depends on the capital available to kick-start the business.

The small-scale cold room business would only entail selling to immediate customers.

For people who want to engage in small-scale cold room business, all you need is a good shop, refrigerators or a mini-cold room, constant power supply and of course, access to a cheap supply of products.

Location:

The success of your business depends largely on the location of the cold room.

According to Obiajulu, cold room must be located in a busy environment— most preferably close to a market.

“Once the cold room is strategically located, definitely people will patronize you, the place must be spacious and well ventilated in order to guarantee the adequate preservation of your products,” she said.

Registration:

An important step for any serious operator (large scale) of a cold room is to register with the regulatory agency, the National Agency for Food Drugs Administration and Control (NAFDAC). Officials from NAFDAC will visit the premises and give a pass mark on the hygiene of the environment since you will be storing consumable goods. It is therefore advisable to get the necessary government license and get your premises registered.

Access to products:

If you plan to deal in chicken, turkey, meat, and fish, you can set up a farm where you can raise livestock birds or get supplies from owners of big poultry farms, then process and package the goods by yourself before selling. You can make more profit with these arrangements.

Equipment needed to operate a cold room

For a small-scale cold room business, the main pieces of equipment are:

· One or two deep freezers:

· A stabilizer.

· A generating set

For those that want to start on a large scale:

Buying or constructing a cold room— Currently, prices of cold rooms vary with the number of features such as cold room dimension, the thickness of polystyrene body panels, roof panels, floor panels and door type sliding or hinged door.

A cooling van for transportation of perishable goods

Generating set

There are cold rooms of different capacities (3tons to 500tons) available in the market. They are either imported or locally built in Nigeria. The imported cold rooms are very expensive, but the locally fabricated cold rooms are affordable and cheap to maintain; this will reduce the capital needed.

Because of the peculiarity of this business, an operator must ensure constant power supply to prevent the products from damage. And to ensure steady power supply, you need a standby generator as an alternative to the public power supply; this is to ensure the continuous functioning of your cold room.

Also, to get new customers, retain old ones and possibly gain an advantage over existing competitors, you will need to purchase one or two cooling vans to aid fast delivery of frozen foods to various destinations without them getting worse.

Other tools include

· Cutting knives

· Packaging supplies

· Measuring scales, tables.

· Polythene bags or cartons.

· Bowls and safety equipment.

Also, hire some hands to manage the cold room business to ensure a high profit. You will need services of a manager, sales boys, loaders, driver, and security men.

Likely Challenges

The biggest challenge faced in the business is the shortage of electricity. This is why getting a standard generator that can carry the cold room is mandatory and this will always gulp very high voltage.

Another one is transportation because the goods can be on the way for days, even weeks and there might be an accident or break down of the vehicle along the way.

How much does it cost to make a cold room?

Details Of Cold Room Construction Cost.

Contrary to what the name implies, a cold room is more than just a refrigerator for your restaurant. Also known as “cold storage,” it is a key aspect of the food supply and distribution network. Changes in food processing, purchasing, and consumption have led to cold storage construction becoming a top priority for supply chain players. If you are looking to build a cold room, you may be wondering what factors go into the process? For that matter, how much does cold room construction cost?

type of cold room construction

First and foremost, you need to select the way in which you approach the construction. There are numerous options that can help determine the best design for each cold storage facility. Choosing a construction type is an important facet when it comes to a building’s insulation and cooling. New construction for cold storage can be done with insulated metal panels, insulated concrete (be it tilt-up or precast), or both.

Additionally, a dry warehouse can undergo conversion to transform into a freezer/cooler. This is possible by installing insulated metal panels inside existing walls. This is a “box-in-a-box” option, and it is a great solution when the location you have your eye on is in a heavily built-up area. Specifically, an area with minimal land available. This allows a cold storage user to convert ambient space into a cooler, freezer, or cold dock.

temperature control

When designing, you must consider how adjacent temperatures, product, and equipment loads can affect the spaces. At this point, you need to figure out how to achieve the necessary R-value for a cold room. For context, the R-value measures how well a two-dimensional barrier resists the conductive heat flow. Such barriers usually include a layer of insulation, a window, wall, or ceiling. After identifying the R-value requirements, you can move forward with selecting refrigeration equipment.

The expected operating cost, drawing from local power costs, is an additional key component in equipment selection. It also has a hand in determined R-values. It can potentially have cost implications for the end-user following the construction of the cold storage. However, by increasing the R-value, you could counterbalance the operating expenses and cost of mechanical system premiums.

power supply and backup system

Cold storages consume a huge amount of power, with the lighting and HVAC systems utilizing most of it. Other components that require power are automatic doors, security monitors, and response systems. All of this adds to operational costs, which if you do not adhere to specific guidelines, can rapidly rise.

Furthermore, an additional power supply source being readily available as an alternative will boost costs even further. This backup power source, even at a bare minimum, must be strong enough to preserve the necessary temperatures. This way, the perishable goods will remain in good condition.

sanitary conditions

Sanitary maintenance in storage environments is crucial for cold rooms where food is undergoing processing. These types of facilities are subject to frequent cleanings. This is why smooth construction methods are incorporated into the foundation, structure, finishes, trims, and other factors. These techniques get rid of recesses and crevices in order to hinder bacterial growth. Additionally, it reduces the chances of water collecting and languishing.

Another pivotal cold room construction technique is the floor heating system installation. Adding heat to an environment where it is nonessential seems counterintuitive, but it helps dry the floors after cleaning. Any moisture present in food storage or processing settings can increase the amount of bacteria. Consequently, it jeopardizes the food supply.

Maintaining your cold room is important, from the sanitary conditions to the aforementioned temperature control. One must also dedicate specialize in facility maintenance .

Above-ground vs. below-ground cold room construction cost

The average above-ground unit derives from modular construction that presents fabricated metal panels with a 34 R-value. HVAC unit installations occur indoors, often settling close to a metal pole barn. This way, it saves on insulation, lumber, and concrete. Costs for electricity also experience a rise due to an increase in heat conduction gain. In total, the costs of such a unit are roughly Rs3300,000. A basement unit, on the other hand, incurs upfront costs that typically exceed Rs500,000.

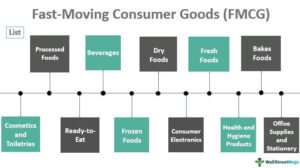

Top most festival Products FMCG consumers search today

World Wide Festive Trends Decoded What Indian festive consumers seek...

Read MoreHow right selection of FMCG Salesmen improves brand market share

How can FMCG Companies improve salesman’s technique in order to...

Read MoreHow most searched Fmcg sales and marketing words help newbie salesman

Why undestand FMCG sales management? Sales management is the process...

Read MoreHow Successful FMCG Salesman Starts his Day, a guide

How does one become a good sales executive in the...

Read More

Pingback: Top Trusted and Most Searched JobSites In Hongkong every day

Pingback: Fmcg Salesmen Reasons to Change Distributor Newbies Beware?

Pingback: Can I invest start a food business with or without a shop?